The roof went on before any additional support could be added, but I like the idea of adding the bracing by the ties. I have a few weeks before any work is slated for the underside of the trusses.

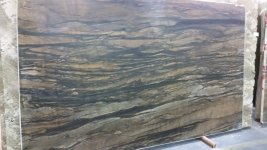

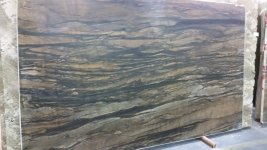

We've finally settled on our granite for the counter tops. Sandalus in the kitchen. Fusion in the master bath and Viena Oro in the guest bath and for the basement bar.

In the last few days, we met with someone to help us plan our lighting options. Also a quick walk-thru with the electrician and with the insulation and sheetrock folks. Got the whirlpool, toilets and bath sinks ordered - but holding off on the hardware (faucets/lines) until we get a little further along.

I'm still trying to decide what kind of outdoor floods to use. My goal is to be able to light 360 degrees around the house. I'd like to hear thoughts on halogen vs LED. Indoors, I really want to go with LED as much as possible but have concerns on flicker. Opinions seem to vary widely on this - especially since almost every switch in the house will be a dimmer.

The fireplace, a Superior WCT40CRWSI, should arrive next week.

Our 2500' power/water trench from H___ is still unfinished. This has been a nightmare and a financial disaster - lol. The electrical conduit has been strung out along the run and fill gravel has been delivered. I cannot wait until this thing is filled in and I can stop thinking about it!!!!! Water from the well will join the trench about midway. Also, we learned the local electrical coop will be expanding their fiber Internet service to the area next year. So, we're adding a run of 1" conduit.

The ground floor windows "may" be installed on the 28th, assuming the delivery goes as planned. Although the upper windows in the great room will still be open, I think the house will be dry. We'll get on those as soon as the lowers are in place. The uppers will be cut-to-fit and we need to lowers in first to be sure all the upper/lower panes wind up in alignment.

Finally, all the trash/debris left behind by the builders is getting cleaned up. A lot of it resulted from tear-out, as we tended to change our minds along the way

The upstairs room is one example - going in AFTER the rafters had been installed. Some of the lumber was reused but quite a bit hit the pile. I've been culling through it as I go and have started stacking what is best to be used for my own list of projects. As soon as I get the area clear, I'll be ready to have the front/rear porches and the driveway poured.

Things are inching forward and the house is beginning to take some shape. I also tore down my "temporary" well-house and had it rebuilt with blocks. Some of the scrap lumber will be used for the roof. And, just to be sure we never get any rest, someone recently crashed a car into one of our rental properties. LOL We decided to do a complete remodel - just completed.