SullysTractor

New member

Hello everyone,

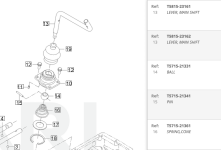

This weekend when I was operating my CK3510 I went to shift into reverse and the main shift lever broke off. The part that broke off is the piece that attaches to the transmission. On this section, one end goes into the transmission and the other end has a 90 degree bend on it which is bent straight up with two holes tapped into it. It snapped off right where the threaded holes were tapped into the shaft. The second section of the shift lever that has the shift knob on it is not broken. In fact I was able to remove the two bolts that would normally attach it to the lower main shift lever, pull what was left of the broken piece that slips into the upper lever and barely slip it onto what was left of the lower shift lever in order to drive the tractor back to the house.

I looked into the service shop manual to see if I could identify what part would actually need replacing and if it was something I could do myself. It looks like the lower main shift lever might be able to be removed so I could either get it repaired or replaced. I am capable, and normally do my maintenance services and other repairs on this tractor and my other vehicles I have. however I am not wanting to tackle opening up the transmission because it looks like something I could get in over my head.

Has anyone ever removed the main shift lever on a 3510 without opening up the transmission? My other option is to slip the upper lever over what is left of the lower shift lever and weld it. This might be the easiest way however if the transmission ever needs to be removed the welded lever could become an issue. I would appreciate any advice on this. Thank you, Sully

This weekend when I was operating my CK3510 I went to shift into reverse and the main shift lever broke off. The part that broke off is the piece that attaches to the transmission. On this section, one end goes into the transmission and the other end has a 90 degree bend on it which is bent straight up with two holes tapped into it. It snapped off right where the threaded holes were tapped into the shaft. The second section of the shift lever that has the shift knob on it is not broken. In fact I was able to remove the two bolts that would normally attach it to the lower main shift lever, pull what was left of the broken piece that slips into the upper lever and barely slip it onto what was left of the lower shift lever in order to drive the tractor back to the house.

I looked into the service shop manual to see if I could identify what part would actually need replacing and if it was something I could do myself. It looks like the lower main shift lever might be able to be removed so I could either get it repaired or replaced. I am capable, and normally do my maintenance services and other repairs on this tractor and my other vehicles I have. however I am not wanting to tackle opening up the transmission because it looks like something I could get in over my head.

Has anyone ever removed the main shift lever on a 3510 without opening up the transmission? My other option is to slip the upper lever over what is left of the lower shift lever and weld it. This might be the easiest way however if the transmission ever needs to be removed the welded lever could become an issue. I would appreciate any advice on this. Thank you, Sully