OK YOU GUYS JUST STOP IT!!!

(IE...kidding).

It's bad enough when my NOT tractor savy wife comes out and says "you building another boom pole?" I assure you boom pole is NOT something that rolls off her tongue daily.

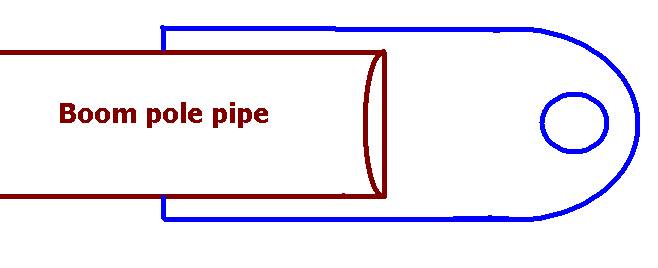

Ron... Thought about using the triangle but this was just 2 darn easy. the 1x2 tubing is actually 12ga I think, It's not 16ga. In my other test lifts I didn't see any stress here. But I have more tubing and another free Saturday comming up so who knows.

schmism.. Same as Ron, actually I liked the KK (TSC) boom pole because it used a simple piece of angle for the cross piece with welded on links. If this one works out the double as a trailer hitch is a bonus..my current trailer mover is on sort of a utility 4x4x3/8" piece of tubing. I use the tubing to hold a middle buster, cultivators, subsoilers, etc. It much heavier. This is an upgrade.

ovrszd...and then a V4.0, 5.0, ........

mikim... Angelton? From time to time. My parents sold their beachhouse and I'm up in Spring now. But since I've got the welder, bring it up and we'll put something together!! Of course my tractor and all the fun stuff is in east Texas....Elkhart.

ovrszd...#2...Actually the "no top link" design is working out well. And while I was looking around yesterday I noticed that if you have a PTO post hole digger? You have half the boom pole already made. Because the PTO diggers I saw did not use a top link. So in that case all you need is a pole.

schmism...#2 ....call me lazy I guess. Came this close to doing that but didn't feel like getting hotter anymore. With our heat and humidity, cutting and welding is a watersport for a sweater like me. When my son was helping me he asked once "is that sweat?". Yep...sweat was running off the helment in a stream. So I decided enough heat for a day!! I fell asleep watching NASCAR...

Thanks for the comments gentlemen!

Rob

This one is getting heavier. You can also see where I modded the lift arm connection. So my arms should be able to go all the way to the ground. I just sort of hacked in the cut outs but had a little T left over and welded it on for a trailer hitch.

This one is getting heavier. You can also see where I modded the lift arm connection. So my arms should be able to go all the way to the ground. I just sort of hacked in the cut outs but had a little T left over and welded it on for a trailer hitch.