Renze

Elite Member

Does anyone have some good tips on bodywork sheetmetal working ?

I need to weld some pieces into the mudguards of my old 3011 but i'd better ask here first, before i try to make custom shop press dies...

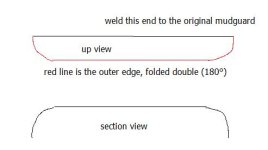

I need two rounded edges, thats not so hard to bend over a piece of wood. But it also needs a 180ー folded edge, which isnt in a straight line but also a curve on the outer edge of the mudguard.

Whats the best practice ? What tools do i need, are those expensive, and if so, what can i use as a substitute ?

I need to weld some pieces into the mudguards of my old 3011 but i'd better ask here first, before i try to make custom shop press dies...

I need two rounded edges, thats not so hard to bend over a piece of wood. But it also needs a 180ー folded edge, which isnt in a straight line but also a curve on the outer edge of the mudguard.

Whats the best practice ? What tools do i need, are those expensive, and if so, what can i use as a substitute ?