Cord

Veteran Member

Succeeded in breaking my log splitter this past weekend. Since I built it 15 years ago, it's been pretty reliable, but looking back I was really pushing my luck. A curly piece of wood got stuck in the head and I was trying to clear it using another piece of wood to push it through. Well, that second piece of wood had a layer of frost on it and it shot out like it had been loaded into a cannon. The 40lb chunk punched a lady standing next to the splitter in the gut and it took her right off her feet. She flew back about 3' and landed on a pile wood debris. The landing looked fairly gentle with her feet rotating up in the air. Rung her bell pretty well on the frozen ground but is otherwise ok. I can't believe she doesn't have broken ribs.

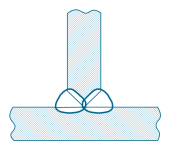

Looking at the splitter, when that piece of wood shot out it totally sheared the head off the rail. The metal piece that broke was 3/4" thick and 6" long. It ripped the metal lengthwise. The there was no discernable grain to the metal. Amazingly, my welds didn't fail. It's going to be a major project, but I already have new material on order and will be beefing it up. I need to get some pictures, but now just work off the description. I will be welding a T joint between two very thick pieces of metal. The vertical member is a 3/4" bar that has a fillet weld on both sides of the end. One side was then reinforced with a piece of 1/2" metal. There are three welds with the inner weld being concealed by the reinforcement. The horizontal member will be the 1" plate that I'm replacing. I'm seriously thinking about Ving out the T joint so I can get better penetration into the center of the joint. Thoughts on this? Due to access reasons, I think the V will be asymmetrical with the larger weld being on the outside. I've never welded anything so thick, so I could use some parameters. I'll be using GMAW, .045 and C02 and a 350a machine. I presume this needs to be preheated to keep it from warping? Once I start welding, should I stop to control the temps or keep making passes? Because all of the weld is on one side of the new 1" plate, I'm somewhat concerned about it warping. I presume I can help this by heating the backside?

Looking at the splitter, when that piece of wood shot out it totally sheared the head off the rail. The metal piece that broke was 3/4" thick and 6" long. It ripped the metal lengthwise. The there was no discernable grain to the metal. Amazingly, my welds didn't fail. It's going to be a major project, but I already have new material on order and will be beefing it up. I need to get some pictures, but now just work off the description. I will be welding a T joint between two very thick pieces of metal. The vertical member is a 3/4" bar that has a fillet weld on both sides of the end. One side was then reinforced with a piece of 1/2" metal. There are three welds with the inner weld being concealed by the reinforcement. The horizontal member will be the 1" plate that I'm replacing. I'm seriously thinking about Ving out the T joint so I can get better penetration into the center of the joint. Thoughts on this? Due to access reasons, I think the V will be asymmetrical with the larger weld being on the outside. I've never welded anything so thick, so I could use some parameters. I'll be using GMAW, .045 and C02 and a 350a machine. I presume this needs to be preheated to keep it from warping? Once I start welding, should I stop to control the temps or keep making passes? Because all of the weld is on one side of the new 1" plate, I'm somewhat concerned about it warping. I presume I can help this by heating the backside?