kubotaswede

New member

20 years ago I imported a B21TLB to Sweden from the US. The machine has been incredible problem free. However, yesterday I identified a hydraualic oil leek coming from the oil cooler return pipe located at the third bend counted from the front. A section of the pipe is corroded and the leak is significant. Replacement or repair is mandatory. Buying the spare part (Kubota no 32721-39323) in Sweden is impossible and Kubota dealers in the US are not allowed to export. So how do I solve this problem? The first issue was to remove the faulty line which required removal of the hood, grill, hydrualic oil filter protector and protecting cover under the seat. Needless to say all bolts were stuck so heat and long handles had to be used. Now the pipe is loose but I can not remove it from the tractor due to its complex form and the narrow spaces in which it is running. My questions are:

1. Anyone know how to operate the pipe to get it off the tractor in one piece? Do I have to remove more items or should I just cut the pipe into three pieces?

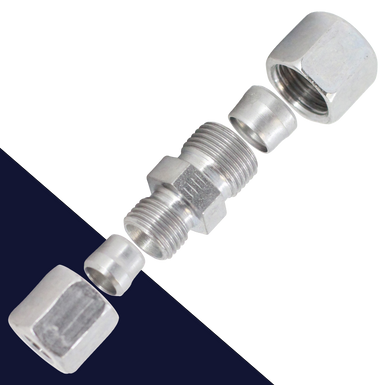

2. Would it be safe to replace the major part of the pipe with a hydraulic hose or should I just remove the corroded section, bend a fresh 12 mm pipe and connect it back with shear ring connectors?

3. Is welding or hard soldering of a corroded pipe to recommed should I get it off the tractor in one piece?

Any suggestions would be highly appreciated.

Lars

1. Anyone know how to operate the pipe to get it off the tractor in one piece? Do I have to remove more items or should I just cut the pipe into three pieces?

2. Would it be safe to replace the major part of the pipe with a hydraulic hose or should I just remove the corroded section, bend a fresh 12 mm pipe and connect it back with shear ring connectors?

3. Is welding or hard soldering of a corroded pipe to recommed should I get it off the tractor in one piece?

Any suggestions would be highly appreciated.

Lars