I've had a look into the service manual and confirmed the open center system & fixed displacement (gear) pump. @K7LN you were right, I was wrong.

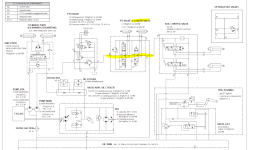

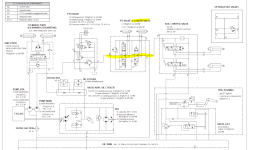

After tracing out the hydraulic schematic I realized a few more limitations imposed on me by this system, that I hadn't realized before because I've never needed to use them. I've only had this tractor a few months and in that time pretty much only used it as a forklift.

- I can't lift the 3-point while moving the FEL

- I can't use the FEL while using either of my remotes

- I can only use one remote at a time

- I probably can't engage the PTO while running the FEL or remotes (unable to test, but I did confirm that once PTO is engaged it stays engaged and other hydraulic functions work)

I brainstormed on the question "ok, so then how is it possible that I can lift + curl occasionally, if I have enough engine RPM and I feather the controls?" This is the hypothesis I came up with:

PART A: The directional control valves are not "digital" (bang-bang), but more "analog" (proportional) when hand-operated between extremes. If I pull the FEL joystick all the way back (lift), then 100% of the flow is sent to the lift cylinders and 0% of the flow is permitted to continue downstream to the curl valve, aux valves, and 3-pt. But if I only pull half-way back on the joystick, then 50% of the flow is diverted into the lift cylinders, and the other 50% is permitted to continue on through the valve and in theory should be available to the downstream valves. That part of the hypothesis I feel pretty confident about. The following is just a fart in the wind suspicion...

PART B:

NOW, if I try to

use that remaining 50% of flow

to actually do some work, things get wonky. When I start actuating downstream valves, that causes backpressure on the lift valve that I'm currently feathing @ 50% by hand. The downstream load robs from from FEL lift load, and the original 100% pressure @ 50% flow is no longer available to the lift cylinders. If the backpressure generated by downstream load (let's say curl) exceeds the pressure needed to continue lifting, then lift ceases altogether (and theoretically could start lowering back down, maybe... IDK) and that downstream load may or may not work to some extent, or at all. In this case, the only way to get any measure of success in actuating the two functions at once, is to go balls-to-the-wall with the pump and hope that there's enough pressure and flow to satisfy both series valves at least to the extent that you get some minor amount of movement in the desired direction.

Does that sound correct? It at least seems to explain my observations. When I fully actuate any of the valves which are in series, none of the other valves work (I think upstream valves have precedence) and when I feather any two of the series valves simultaneously, weird inconsistent (sometimes desirable) things happen.

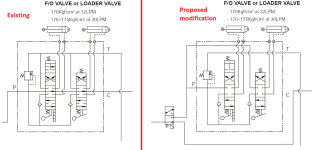

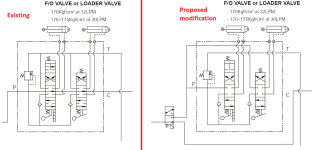

Moving on, the diagnosis of "no cure" seems reasonably accurate. But I'm not always reasonable. I'm kicking around a few ideas; here's the seemingly most promising one:

I change the open center series valves for FEL with plain DCVs plumbed in parallel. To prevent the pump pushing full flow over a relief valve any time the FEL isn't moving (and to enable continued use of downstream functions: AUX & 3-point) I install a normally open solenoid bypass valve. Microswitches get installed on all 4 axes of the joystick, so that any time the joystick is centered, the entire FEL circuit is bypassed and fluid only goes to AUX & 3-point. Any time I move the joystick in any direction, the solenoid actuates and the FEL is switched back into the circuit. While the FEL is in the circuit, the valves are in parallel, so both should be presented the same pressure and be free to consume as much flow as they require.

Seem like plausible solution?