SensibleNick

Gold Member

We only just got the tractor, and we're in a-rush to get our veg-patches sorted.

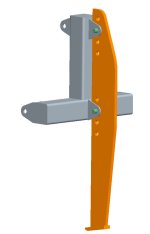

Having borrowed a 2-share plough from a friend and discovered that a) it was HUGE and b) it needed serious repairing, I've decided to make do with a subsoiler instead. From what I've read, fewer people are ploughing these days anyway. I've got a rototiller, and just need to break up the soil a bit before I get serious on it.

So.. I've got my hands on some 90x90mm square section, and a length of 150mm x 15mm strip.

Hopefully I'll get time to cut the parts this weekend, and get started on my first bit of home-built tractor kit.

Total Length of the blade is 980mm, and the securing pins will be steel (top) and Aluminium (bottom) to allow some sort of shear protection. I might end up using the frame for something else later.

Having borrowed a 2-share plough from a friend and discovered that a) it was HUGE and b) it needed serious repairing, I've decided to make do with a subsoiler instead. From what I've read, fewer people are ploughing these days anyway. I've got a rototiller, and just need to break up the soil a bit before I get serious on it.

So.. I've got my hands on some 90x90mm square section, and a length of 150mm x 15mm strip.

Hopefully I'll get time to cut the parts this weekend, and get started on my first bit of home-built tractor kit.

Total Length of the blade is 980mm, and the securing pins will be steel (top) and Aluminium (bottom) to allow some sort of shear protection. I might end up using the frame for something else later.