Shield Arc

Super Member

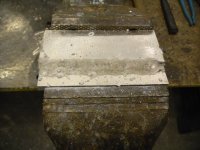

Picked up some 1/8-inch Lincoln Aluminweld 43 rod the other day. Did some playing around with it this morning. I've had this 1/4-inch aluminum plate for at least 30-years laying in the junk pile. Took a stainless steel wire wheel and cleaned it up, and tacked up some lap joints. I played with the arc force, but it seemed to work best at 0.0 on the arc force, and 125-amps. I ran it with a back and forth whip motion, (like 6010) with a lot of rod angle trying to force the slag behind the puddle. This stuff burns fast, you have to make sure your hands are not in any kind of a bind, because you won't have time to adjust. You also have to hold a very close arc, I found it ran best when I just jammed the rod right into the puddle! This weld is 4 3/4-inches long, one rod! She don't go very far.