Needless to say the results of my purchase hasn't been what I've wanted. I have a mx6 bushhog and really need to offset it at least 6" and 1' would be better. Does anybody have an idea how to go about this? I've been racking my brain and keep coming up short. I figure on haveing to use a 2nd gearbox

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

adaptor to offset 3pt hitch bushhog.

- Thread starter exiled

- Start date

- Views: 37292

More options

Who Replied?

/ adaptor to offset 3pt hitch bushhog.

#1

Kays Supply

Veteran Member

I mounted a bushhog on my father in law's Super A many years ago. It had the offset seat. I took two slabs of steel and made a chain offset for the PTO. I used shaft and sprockets from a farm store. It was over 30 years ago and this past year I had to replace the chain for him.

If your tractor has more hp than Super A you might have to double the chain , or even try a V belt set up.

If your tractor has more hp than Super A you might have to double the chain , or even try a V belt set up.

blueriver

Super Member

- Joined

- Oct 4, 2007

- Messages

- 5,012

- Location

- S.E.Oklahoma

- Tractor

- JD 5520 Montana 4340 Farmall Super A Montana 5720C

Needless to say the results of my purchase hasn't been what I've wanted. I have a mx6 bushhog and really need to offset it at least 6" and 1' would be better. Does anybody have an idea how to go about this? I've been racking my brain and keep coming up short. I figure on haveing to use a 2nd gearbox

Why the need to offset it?

DaveOmak

Platinum Member

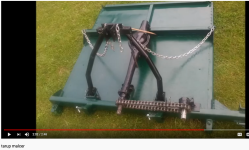

This is what I have done to my mower... I'm not sure if it will work for you... Maybe it will give you some ideas as to what could be done.. The reason for my offset was to have the mower cut outside the right rear tire to get closer to sprinklers and fences etc... Keep in mind the PTO shaft when doing the modification.... Notice the original pins are still useable... something you might consider, if possible..

Dave

Dave

Attachments

slowzuki

Elite Member

- Joined

- Sep 19, 2003

- Messages

- 4,156

- Location

- New Brunswick, Canada

- Tractor

- Kubota L5030 HSTC, MF 5455, Kubota M120, Allis Chalmers 7010

On my Kubota I just pin the 3 point arms over to one side as far as they go. Get about 12-18 inches of offset.

Needless to say the results of my purchase hasn't been what I've wanted. I have a mx6 bushhog and really need to offset it at least 6" and 1' would be better. Does anybody have an idea how to go about this? I've been racking my brain and keep coming up short. I figure on haveing to use a 2nd gearbox

Do you not have to do anything for the pto shaft? I was thinking going past 5 inches would strain the pto.On my Kubota I just pin the 3 point arms over to one side as far as they go. Get about 12-18 inches of offset.

Dave that looks good what you did. Yea that should work for me as I'm doing it for the same reason you are. Does your unijoints not bind up?

I had a bad expernace getting my tractor and bushhog. I mean it was really awful. Well I asked for a mx8 bushhog. Well they didn't have one in stock so instead of ordering one they "sold me" my mx6. Meaning they sent the paperwork to jd credit. I found out about it when I picked up my tractor. I started arguing that I got an mx8 but sure as the world right there on the paperwork was mx6. I paid for an mx6 so there wasn't much else to say about it. Now for the time being I'm stuck with it.

blueriver

Super Member

- Joined

- Oct 4, 2007

- Messages

- 5,012

- Location

- S.E.Oklahoma

- Tractor

- JD 5520 Montana 4340 Farmall Super A Montana 5720C

Do you not have to do anything for the pto shaft? I was thinking going past 5 inches would strain the pto.

Dave that looks good what you did. Yea that should work for me as I'm doing it for the same reason you are. Does your unijoints not bind up?

I had a bad expernace getting my tractor and bushhog. I mean it was really awful. Well I asked for a mx8 bushhog. Well they didn't have one in stock so instead of ordering one they "sold me" my mx6. Meaning they sent the paperwork to jd credit. I found out about it when I picked up my tractor. I started arguing that I got an mx8 but sure as the world right there on the paperwork was mx6. I paid for an mx6 so there wasn't much else to say about it. Now for the time being I'm stuck with it.

Now I understand the offset ... I don't believe you have to concern yourself with the pto shaft ... my hay cutters set straight behind the tractor but the pto shaft itself is a good 8-10" offset ... keep those u-joints greased.

Oh yea I love the grease. Saturdays I grease everything on the tractor. I grease the FEL after each really good workout like move hay around. In which I grease all 4 axles. I grease all my attachments as I'm hooking em up. I don't mind wearing out a grease fitting at all. My wife makes fun of me.Now I understand the offset ... I don't believe you have to concern yourself with the pto shaft ... my hay cutters set straight behind the tractor but the pto shaft itself is a good 8-10" offset ... keep those u-joints greased.

BHD

Veteran Member

I had a small 5 foot mower, I off set so it would mow even with one wheel of the tractor,

I reversed one of the three point pins, (the up rights were flat iron), and then made a extended shaft for the other side, and then made a small bracket to support the rod, it was simple and did not permanently alter the mower in any way, I could mow up to my trees and not leave a unmowed strip where the tire was wider, worked well, I do not think I did any thing with the top link,

I reversed one of the three point pins, (the up rights were flat iron), and then made a extended shaft for the other side, and then made a small bracket to support the rod, it was simple and did not permanently alter the mower in any way, I could mow up to my trees and not leave a unmowed strip where the tire was wider, worked well, I do not think I did any thing with the top link,

grsthegreat

Super Star Member

I have the same issue with my new tractor (74" rear wheel width) and my 60" JD bush hog. Was going to try and just jog it over to one side and see how the pto thing works out.

blambmn

New member

This is what I have done to my mower... I'm not sure if it will work for you... Maybe it will give you some ideas as to what could be done.. The reason for my offset was to have the mower cut outside the right rear tire to get closer to sprinklers and fences etc... Keep in mind the PTO shaft when doing the modification.... Notice the original pins are still useable... something you might consider, if possible..

Dave

I'm curious. What is the angle iron is that is bolted to the side of your mower?

DaveOmak

Platinum Member

Sorry for the late reply... I have a few rocks that come up with the freeze / thaw cycle... they were beating the krap out of the mower housing... Sooooo, I cut out the side of the mower and bolted a chunk of 1/2" thick belting to cover the cut-out... Also, once the rocks were hit by the blade, they would bang around, under the mower deck and wreak havoc.... The hunk of belting really slows the rocks down a lot... and they can even escape if they are lucky ... LOL...

I'm curious. What is the angle iron is that is bolted to the side of your mower?

sandman2234

Super Member

- Joined

- Dec 4, 2005

- Messages

- 6,688

- Location

- Jacksonville, Florida

- Tractor

- JD2555 and a few Allis Chalmers and now one Kubota

Just thinking...

IF you take Dave's picture and unbolt the gearbox, and turn it just a little bit, say maybe 1/8 of a turn, and re-drill the holes in the deck, that would lessen the strain on at least one of the u-joints.

David from jax

I need to offset an 8 foot twin spindle mower, about two more feet, so doing it this way probably won't work.

David

IF you take Dave's picture and unbolt the gearbox, and turn it just a little bit, say maybe 1/8 of a turn, and re-drill the holes in the deck, that would lessen the strain on at least one of the u-joints.

David from jax

I need to offset an 8 foot twin spindle mower, about two more feet, so doing it this way probably won't work.

David

Joe Batt

Silver Member

I wouldn't do that. You want the input and the outputs of the shaft to be parallel, otherwise there will be "accelerations" between the input and output. Think of this: As you pass through a u-joint with an angle in it, the output will not be spinning at an even speed. It will constantly be accelerating and decelerating. If you have two u-joints, they can cancel each other. So, if the gear box and the PTO are parallel, the shaft may have accelerations, but the mower will not.Just thinking...

IF you take Dave's picture and unbolt the gearbox, and turn it just a little bit, say maybe 1/8 of a turn, and re-drill the holes in the deck, that would lessen the strain on at least one of the u-joints.

David from jax

I need to offset an 8 foot twin spindle mower, about two more feet, so doing it this way probably won't work.

David

ptsg

Super Member

jmc

Elite Member

- Joined

- Jul 21, 2003

- Messages

- 3,197

- Location

- SW Indiana

- Tractor

- Ford 1920 4x4 (traded in on Kubota). Case 480F TLB w/4 in 1 bucket, 4x4. Gehl CTL60 tracked loader, Kubota L4330 GST

I seem to remember from a class 50 years ago that 11 degrees is the maximum shaft angle for u-joint longevity. So if your distance between u-joints is 60 inches (probably shorter) then 11-12 inches of offset should be safe. That's if the PTO shaft is running more or less horizontally. If not, some of that offset is wasted vertically in a compound angle. But that can be calculated too.

airbiscuit

Super Member

- Joined

- Aug 28, 2004

- Messages

- 7,634

- Location

- NW Wisconsin

- Tractor

- New Holland T2310 (40hp), Kubota L3010 GST, New Holland TC21DA *** Previously - Farmall H, 1941 John Deere B, Shibaura SD1500, John Deere 850, Bobcat 642, New Holland 1925

Reversing one 3pt pin is an easy and fast first start. That allows you to shift your 3pt arms a fair amount.I had a small 5 foot mower, I off set so it would mow even with one wheel of the tractor,

I reversed one of the three point pins, (the up rights were flat iron), and then made a extended shaft for the other side, and then made a small bracket to support the rod, it was simple and did not permanently alter the mower in any way, I could mow up to my trees and not leave a unmowed strip where the tire was wider, worked well, I do not think I did any thing with the top link,

jmc

Elite Member

- Joined

- Jul 21, 2003

- Messages

- 3,197

- Location

- SW Indiana

- Tractor

- Ford 1920 4x4 (traded in on Kubota). Case 480F TLB w/4 in 1 bucket, 4x4. Gehl CTL60 tracked loader, Kubota L4330 GST

Found that engineering reference for acceptable shaft angle. Turns out a maximum of 15 degrees is recommended, rather than 11 degrees.I seem to remember from a class 50 years ago that 11 degrees is the maximum shaft angle for u-joint longevity. So if your distance between u-joints is 60 inches (probably shorter) then 11-12 inches of offset should be safe. That's if the PTO shaft is running more or less horizontally. If not, some of that offset is wasted vertically in a compound angle. But that can be calculated too.

(That reference also supports Joe Batt's (#15) caution about keeping the input shaft and output shaft parallel.)

Here are some similar links:

- Replies

- 84

- Views

- 14K