After dragging my feet too long, I've decided it's time for a grapple. I can't justify paying $2500+ for picking up logs and I own a fab shop, so let's build one!

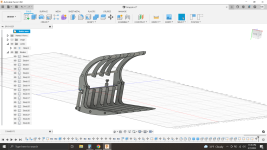

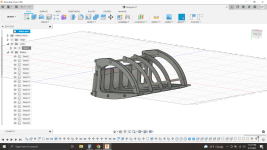

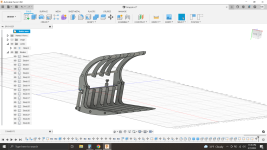

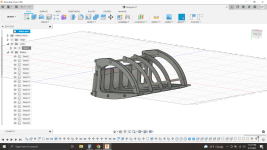

I modeled it all up tonight and have the mechanics worked out. I'll use 1.5"x6" cylinders which will give more than enough clamp force for anything I should be working with. All the DXF files are sent off to be cnc plasma cut in town while I'm on family vacation for the next 2 weeks. Finished weight looks to be about 315lbs before the quick attach plate. No, it's not as "heavy duty" as some commercially available units out there, but it doesn't weigh 650lbs either. I have 1940lbs lift on the new to me Massey 1740M and I don't want to kill the lifting capacity. I'm confident it will be more than up to my needed tasks. Updates will come quickly when I get back!

I modeled it all up tonight and have the mechanics worked out. I'll use 1.5"x6" cylinders which will give more than enough clamp force for anything I should be working with. All the DXF files are sent off to be cnc plasma cut in town while I'm on family vacation for the next 2 weeks. Finished weight looks to be about 315lbs before the quick attach plate. No, it's not as "heavy duty" as some commercially available units out there, but it doesn't weigh 650lbs either. I have 1940lbs lift on the new to me Massey 1740M and I don't want to kill the lifting capacity. I'm confident it will be more than up to my needed tasks. Updates will come quickly when I get back!