Dmacleo

Veteran Member

- Joined

- Sep 11, 2020

- Messages

- 1,866

- Location

- Etna, Maine

- Tractor

- 2010 MF GC2400 Owner, 2012 MF1532 User

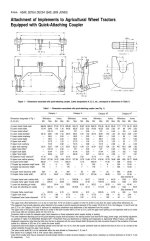

from looks tractor end is (if you account for ruler being shoved in a bit one end and out other end, really ruler from even ball swivel to ball swivel is best) 31" min (within the 32.5 spec for cat II) yet the CAT II implement runs 29.75" which is under the CAT II spec.

dont know how people can run this model implement on this model tractor unless mods were done.

or maybe certain year tractors of this model # had different setup around the drawbar that allowed collapsing arms more.

just my 2c worth, got no experience here, just a thought.

but ruler just showed your MIN width on tractor is LARGER than MAX width on implement.

theres an issue....

dont know how people can run this model implement on this model tractor unless mods were done.

or maybe certain year tractors of this model # had different setup around the drawbar that allowed collapsing arms more.

just my 2c worth, got no experience here, just a thought.

but ruler just showed your MIN width on tractor is LARGER than MAX width on implement.

theres an issue....