The fuel system on the 4310 epowerreverser is designed to inject fuel into the piston

cylinder where heat from compression ignites the fuel and

air mixture.

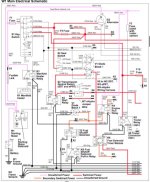

Fuel is supplied to the engine when the fuel shutoff

solenoid is energized. The fuel shutoff solenoid contains

two coils to open the fuel valve. The pull-in coil, in

conjunction with the hold-in coil, overcomes the spring

loaded fuel valve. The hold-in coil keeps the fuel valve open

after the pull-in coil current is removed through the K6 timer

module and the K3 pull-in relay.

The fuel shutoff solenoid is initially energized and pulled in

when the engine run relay contacts close. Voltage is

provided to both of the fuel shutoff solenoid coils (pull-in

and hold-in), which provide enough pull on the solenoid

plunger to overcome the shutoff solenoid spring.

The fuel shutoff solenoid pull-in coil needs a high current

pulse through it to overcome the solenoid spring. After the

solenoid opens (overcomes the spring) a lower current will

hold the solenoid open. The combination of the K3 fuel

shutoff relay and K6 timer module provide a means to

remove the current flow through the fuel shutoff solenoid

pull-in coil after the solenoid opens.

When the key switch is placed in either the run or start

positions, current from the switched power circuit is

provided to the K6 timer module through either the seat

switch and V1 diode block or the rear PTO switch,

transmission neutral switch (SST and ePowrReverser) or

W7 jumper plug (eHydro) and V1 diode block.

This circuit causes the K6 timer module to set its time delay

circuit as well as provide power to the engine run relay. The

engine run relay will energize, closing its contacts to

provide current from the unswitched power circuit wire

002D Red to the 302B and 302C Red wires.

This energizes the hold-in coil of the fuel shutoff solenoid

and provides voltage to the pull-in coil.

At the same time that the engine run relay is being

energized, the K6 timer module will provide temporary

current to the K3 fuel solenoid pull-in relay. With the fuel

solenoid pull-in relay energized, a ground path is created

for the pull-in coil of the fuel shutoff solenoid. This allows

the fuel shutoff solenoid to overcome the spring loaded fuel

valve.

After approximately 3 second the timer module will cut

power to the fuel solenoid pull-in relay. This will open the

relay contacts and remove the ground path for the pull-in

coil.

A ground path for the fuel shutoff solenoid hold-in coil is

provided through the 010N and 010P Blk wires.

A latching circuit is provided to maintain voltage to the

engine run relay after the PTO is engaged.

This circuit allows the operator to leave the seat only after

the following sequence of events has been followed: the

transmission placed in neutral and the park brake locked.

The operator may then leave the seat and engage the PTO.

The engine will shutoff if either the park brake is released

or the transmission is placed in gear without having an

operator present on the seat.