Did do another posting on this over in the Kubota forum. But my follow on questions are more hydraulic oriented.

I did pick up a Kubota B8032 Top and Tilt kit that came with the two cylinders, threaded fittings, 4 hoses and the male quick connects and dust covers. The other kits are not to be had.

The kit has instructions, which lead me to believe this was intended to plug into the BH quick connects when it was removed. Left me less than excited as the third (aux) spool valve is useless for non 3pt implements.

The simplest would be to do it their way but only use a two spool as I cannot envision any use for a third, for anything I expect to do. It would be nice to be able to angle a york rake or back blade, but, that would be a lot of fab work. Maybe two spools sane way to do it. After all, I gotta uncouple hoses anyway and plug em in somewhere.

But, being they procrastinator I am, I'd rather delay the actual purchasing and knuckle busting, so here's a thought to plumb for "always on". That way I could use the third spool (assuming I go for a three spool) for a hydraulic thumb. Someday I may convert the manual thumb.

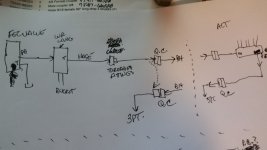

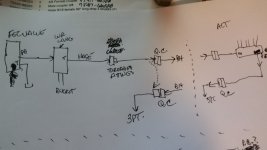

I'll try to attach some rooster scratch drawings that might help explain. I have two questions with the "hard wired" scheme. The tank/return line would T into the tank return of the FEL at the FEL, which requires it to "pump uphill" but hits the T below the height of the 3 spool valve exit (I think, based on where I expect to mount it). Other question is because I don't have a lot of spool valve knowledge, Just enough to be dangerous as they say. Most of them have a Tank and a PB port. Some seem to combine them and somehow function properly. So what I wonder about is, how much flow is there through the Tank port when spools are centered? How much through the PB port when centered? I'd expect "full flow" (valve rating) in last case and much less in the first, but, I think that could be wrong.

The first shows the simple plug in (forgot to name the new local built hose from valve to QC), the second how I propose to T into two existing fittings. Open to helpful comments

Even the other kind if the have some redeeming value . . .

I did pick up a Kubota B8032 Top and Tilt kit that came with the two cylinders, threaded fittings, 4 hoses and the male quick connects and dust covers. The other kits are not to be had.

The kit has instructions, which lead me to believe this was intended to plug into the BH quick connects when it was removed. Left me less than excited as the third (aux) spool valve is useless for non 3pt implements.

The simplest would be to do it their way but only use a two spool as I cannot envision any use for a third, for anything I expect to do. It would be nice to be able to angle a york rake or back blade, but, that would be a lot of fab work. Maybe two spools sane way to do it. After all, I gotta uncouple hoses anyway and plug em in somewhere.

But, being they procrastinator I am, I'd rather delay the actual purchasing and knuckle busting, so here's a thought to plumb for "always on". That way I could use the third spool (assuming I go for a three spool) for a hydraulic thumb. Someday I may convert the manual thumb.

I'll try to attach some rooster scratch drawings that might help explain. I have two questions with the "hard wired" scheme. The tank/return line would T into the tank return of the FEL at the FEL, which requires it to "pump uphill" but hits the T below the height of the 3 spool valve exit (I think, based on where I expect to mount it). Other question is because I don't have a lot of spool valve knowledge, Just enough to be dangerous as they say. Most of them have a Tank and a PB port. Some seem to combine them and somehow function properly. So what I wonder about is, how much flow is there through the Tank port when spools are centered? How much through the PB port when centered? I'd expect "full flow" (valve rating) in last case and much less in the first, but, I think that could be wrong.

The first shows the simple plug in (forgot to name the new local built hose from valve to QC), the second how I propose to T into two existing fittings. Open to helpful comments

Even the other kind if the have some redeeming value . . .

Last edited: