tiger007

New member

Here's my long description of the events leading up to the problem and finally at the end the actual problem I have a question about. Hopefully I provided enough information to start a conversation.

I have a 2012 CK30HST with a remote valve kit dealer installed. Yesterday I had a 5' box blade on the back and a WR Long grapple on the front. The grapple is running off the rear remotes. I have a pair of hoses routed under the tractor to the front to connect to the WR Long Lid Cylinder. I use the Remote Lever from A to N to B to run the grapple open and close. Once I pick something up and its secure in the grapple I move the lever to the N position, but sometime it stays in A or B for a while if I am trying to pull brush or something and need to keep pressure on it.

I typically park the tractor with all the attachments lowered to the ground, grapple was on the ground, box blade on the ground. So I warm the tractor up, lift the box blade and grapple and drive about 500 yards to a small log landing I have. I continued up a rather steep log road to get the grapple close to a tree that was down. I had to get off the tractor to winch the tree into the log road so I could pick it with the grapple. Before I got off the tractor I lowered the box blade to the ground, lowered the grapple and set the parking brake. I got the tree moved into the road, got back on the tractor, lifted the box blade and then used the grapple to pick the tree up. As I was backing down the log road I noticed the box blade didn't appear to be up that high. It was not hitting the ground but it didn't look to be at the full up position, the lever was all the way back so it should have been at max lift. I wrote this off to the incline and my perspective looking down at it.

I got the log to the landing, dropped it and then headed back up the log road to get another log. On the way up one of the box blade teeth hit a stump and made the box blade bounce a bit on the back. It wasn't a "big" hit, I have hit rocks harder working the road but it got my attention. Partly because the box blade should have been high enough to clear anything on the road. The stump is about 3 inches above the dirt in the road.

Alright, we are getting to the problem, thanks for reading this far. I get back up the log road and do the same procedure, lower the box blade, lower the grapple, set the parking brake and get off the tractor to winch another log into the road. When I get back on the tractor is when things got interesting.

I went to raise the box blade and it didn't move. The lever was at 10, all the way to the back and nothing. The arms didn't move or even wiggle. I ran the lever back and forth a few times, nothing, no reaction at the 3PH arm at all. The FEL was working fine, I could lift the grapple, tilt, all that good stuff. The remote valve was working, I could open and close the grapple without any problems.

This was not a good place to be "stuck". Narrow log road cut into a mountain side paralleling a deep ravine on one side and a steep bank on the other side. I'll do another thread on how I got the box blade lifted but for now more about the problem.

I got off the tractor, put some chunks of wood under the rear tires and then pulled the pins on the box blade to the 3PH arms. I could grab the arms and lift them by hand up and down. This doesn't seem good at all, there should have been some type of resistance, or better yet I shouldn't have been able to move them by hand. I got back on the tractor and used the lever again, nothing no movement on the arms at all. I checked the 3PH speed control knob down by my feet. It was about in the middle of its range, but I ran it both directions and tested, nothing, nada, no movement at all on the arms.

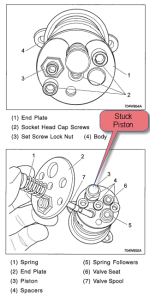

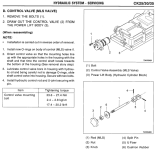

The grapple still works, the FEL still works, just nothing at the 3PH. It was getting dark so I left the tractor there and headed home. At home I consulted the manual, nothing in there about overpressure switches or "neutral" for the 3PH. So I took to google. I didn't find anyone with the same problem. I did find an online version of the service manual. From that it looks like there is a safety valve in the MLS valve...maybe that popped and put the 3PH in neutral? I have no clue really.

I called the dealer this morning. He had no idea what the problem could be and indicated something might be broke inside. It looks like I'll be without a tractor for at least two weeks while they tear into it and try to find the problem. Whatever it is it should be covered under warranty, I hope. The tractor has 120hours on it and is just over a year old.

So, does anyone have a clue as to what could be wrong? I am suspecting a bad valve or broken linkage inside the housing. Or is there something simple I am missing?

In summary:

1. The 3ph was working although it may have been showing signs of loosing pressure due to the lack of lift height (initial observation) and then the hit on the stump.

2. The remote valve still works the grapple.

3. The FEL still works

4. The 3PH arms can be lifted by hand up and then they fall to the ground, very little resistance is felt when lifting them up, both arms lift when lifting only one side, so the shaft inside isn't broken.

5. The 3PH speed control knob didn't have any effect, full slow or full fast or in the middle.

6. The Hydraulic fluid is full

7. 120 hours on tractor

Thanks for any input.

-Tom

I have a 2012 CK30HST with a remote valve kit dealer installed. Yesterday I had a 5' box blade on the back and a WR Long grapple on the front. The grapple is running off the rear remotes. I have a pair of hoses routed under the tractor to the front to connect to the WR Long Lid Cylinder. I use the Remote Lever from A to N to B to run the grapple open and close. Once I pick something up and its secure in the grapple I move the lever to the N position, but sometime it stays in A or B for a while if I am trying to pull brush or something and need to keep pressure on it.

I typically park the tractor with all the attachments lowered to the ground, grapple was on the ground, box blade on the ground. So I warm the tractor up, lift the box blade and grapple and drive about 500 yards to a small log landing I have. I continued up a rather steep log road to get the grapple close to a tree that was down. I had to get off the tractor to winch the tree into the log road so I could pick it with the grapple. Before I got off the tractor I lowered the box blade to the ground, lowered the grapple and set the parking brake. I got the tree moved into the road, got back on the tractor, lifted the box blade and then used the grapple to pick the tree up. As I was backing down the log road I noticed the box blade didn't appear to be up that high. It was not hitting the ground but it didn't look to be at the full up position, the lever was all the way back so it should have been at max lift. I wrote this off to the incline and my perspective looking down at it.

I got the log to the landing, dropped it and then headed back up the log road to get another log. On the way up one of the box blade teeth hit a stump and made the box blade bounce a bit on the back. It wasn't a "big" hit, I have hit rocks harder working the road but it got my attention. Partly because the box blade should have been high enough to clear anything on the road. The stump is about 3 inches above the dirt in the road.

Alright, we are getting to the problem, thanks for reading this far. I get back up the log road and do the same procedure, lower the box blade, lower the grapple, set the parking brake and get off the tractor to winch another log into the road. When I get back on the tractor is when things got interesting.

I went to raise the box blade and it didn't move. The lever was at 10, all the way to the back and nothing. The arms didn't move or even wiggle. I ran the lever back and forth a few times, nothing, no reaction at the 3PH arm at all. The FEL was working fine, I could lift the grapple, tilt, all that good stuff. The remote valve was working, I could open and close the grapple without any problems.

This was not a good place to be "stuck". Narrow log road cut into a mountain side paralleling a deep ravine on one side and a steep bank on the other side. I'll do another thread on how I got the box blade lifted but for now more about the problem.

I got off the tractor, put some chunks of wood under the rear tires and then pulled the pins on the box blade to the 3PH arms. I could grab the arms and lift them by hand up and down. This doesn't seem good at all, there should have been some type of resistance, or better yet I shouldn't have been able to move them by hand. I got back on the tractor and used the lever again, nothing no movement on the arms at all. I checked the 3PH speed control knob down by my feet. It was about in the middle of its range, but I ran it both directions and tested, nothing, nada, no movement at all on the arms.

The grapple still works, the FEL still works, just nothing at the 3PH. It was getting dark so I left the tractor there and headed home. At home I consulted the manual, nothing in there about overpressure switches or "neutral" for the 3PH. So I took to google. I didn't find anyone with the same problem. I did find an online version of the service manual. From that it looks like there is a safety valve in the MLS valve...maybe that popped and put the 3PH in neutral? I have no clue really.

I called the dealer this morning. He had no idea what the problem could be and indicated something might be broke inside. It looks like I'll be without a tractor for at least two weeks while they tear into it and try to find the problem. Whatever it is it should be covered under warranty, I hope. The tractor has 120hours on it and is just over a year old.

So, does anyone have a clue as to what could be wrong? I am suspecting a bad valve or broken linkage inside the housing. Or is there something simple I am missing?

In summary:

1. The 3ph was working although it may have been showing signs of loosing pressure due to the lack of lift height (initial observation) and then the hit on the stump.

2. The remote valve still works the grapple.

3. The FEL still works

4. The 3PH arms can be lifted by hand up and then they fall to the ground, very little resistance is felt when lifting them up, both arms lift when lifting only one side, so the shaft inside isn't broken.

5. The 3PH speed control knob didn't have any effect, full slow or full fast or in the middle.

6. The Hydraulic fluid is full

7. 120 hours on tractor

Thanks for any input.

-Tom