arrow

Super Member

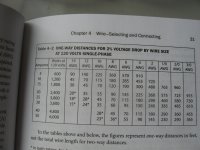

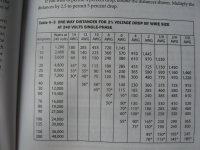

I have two welders. Both small because of the lack of any appreciable service out to the garage. Both welders (one stick the other wire feed) are rated for 140 amps.

I have 10/2, 30 amp 220 circuitry there now.

The small, flux core wire feed I recently acquired has only a 115 plug (daughters pitched in for Christmas and did the best they could) but the 140 stick has a 50 amp terminal end.

CAN I BETTER THE MIG/FLUX TYPE WELDER THAT FITS THIS ELECTRICAL PROFILE THAN WHAT I CURRENTLY HAVE OR AM I STUCK AT 140 AMPS? Most welding done with 1/4" metal with occasional 3/8"-1/2" that the stick can handle. It was good enough to weld a 1" thick splitter wedge on w 1/8" 7018.

What is the limit to wire feed welder amperage output on a 30 amp breaker 220 circuit?

I have 10/2, 30 amp 220 circuitry there now.

The small, flux core wire feed I recently acquired has only a 115 plug (daughters pitched in for Christmas and did the best they could) but the 140 stick has a 50 amp terminal end.

CAN I BETTER THE MIG/FLUX TYPE WELDER THAT FITS THIS ELECTRICAL PROFILE THAN WHAT I CURRENTLY HAVE OR AM I STUCK AT 140 AMPS? Most welding done with 1/4" metal with occasional 3/8"-1/2" that the stick can handle. It was good enough to weld a 1" thick splitter wedge on w 1/8" 7018.

What is the limit to wire feed welder amperage output on a 30 amp breaker 220 circuit?