Marcle

Silver Member

- Joined

- Jun 13, 2012

- Messages

- 151

- Tractor

- Iseki 2140

Have you considered getting all the painted bits hot galv dipped?

Have you considered getting all the painted bits hot galv dipped?

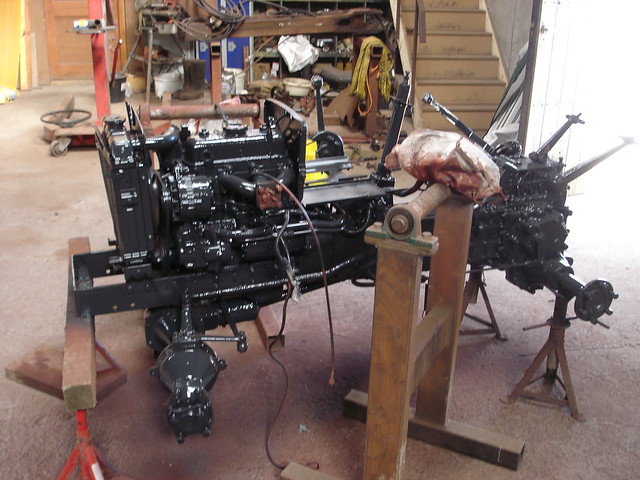

DSC02813 by chrismac2012, on Flickr

DSC02813 by chrismac2012, on Flickr DSC02816 by chrismac2012, on Flickr

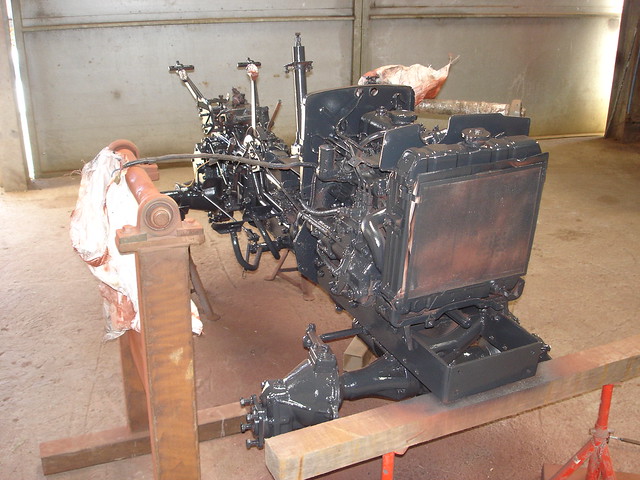

DSC02816 by chrismac2012, on Flickr DSC02815 by chrismac2012, on Flickr

DSC02815 by chrismac2012, on Flickr DSC02817 by chrismac2012, on Flickr

DSC02817 by chrismac2012, on Flickr DSC02818 by chrismac2012, on Flickr

DSC02818 by chrismac2012, on Flickr DSC02819 by chrismac2012, on Flickr

DSC02819 by chrismac2012, on Flickr DSC02821 by chrismac2012, on Flickr

DSC02821 by chrismac2012, on Flickr DSC02822 by chrismac2012, on Flickr

DSC02822 by chrismac2012, on Flickr DSC02824 by chrismac2012, on Flickr

DSC02824 by chrismac2012, on Flickr DSC02825 by chrismac2012, on Flickr

DSC02825 by chrismac2012, on Flickr DSC02826 by chrismac2012, on Flickr

DSC02826 by chrismac2012, on Flickr DSC02827 by chrismac2012, on Flickr

DSC02827 by chrismac2012, on Flickr DSC02828 by chrismac2012, on Flickr

DSC02828 by chrismac2012, on Flickr DSC02829 by chrismac2012, on Flickr

DSC02829 by chrismac2012, on Flickr DSC02830 by chrismac2012, on Flickr

DSC02830 by chrismac2012, on Flickr DSC02831 by chrismac2012, on Flickr

DSC02831 by chrismac2012, on FlickrAll looks good. Can you post a photo of the side facing the tractor (DSC02829). Oil tank of backhoe. So I can advise on ports for hydraulics, or are you now sorted on what goes where.

DSC02840 by chrismac2012, on Flickr

DSC02840 by chrismac2012, on Flickr DSC02841 by chrismac2012, on Flickr

DSC02841 by chrismac2012, on Flickr DSC02842 by chrismac2012, on Flickr

DSC02842 by chrismac2012, on Flickr DSC02843 by chrismac2012, on Flickr

DSC02843 by chrismac2012, on Flickr DSC02844 by chrismac2012, on Flickr

DSC02844 by chrismac2012, on Flickr DSC02845 by chrismac2012, on Flickr

DSC02845 by chrismac2012, on Flickr DSC02846 by chrismac2012, on Flickr

DSC02846 by chrismac2012, on FlickrLooks brilliant!!

How did you get the engine/chassis part done? Do you have a sand-blaster in the house or something?

May i ask how you did degrease? Just throw a lot of wd-40 at it?

I am asking because i bought this 40 year old Ursus C360 tractor. In everything 4 times the size and power of my little iseki's (3000kg, 4cylinder 3 liter diesel, 60HP). But everything is wrong with it, i will have to take it totally apart. If i can handle this, i want to do the same like you did on the iseki.

DSC02847 by chrismac2012, on Flickr

DSC02847 by chrismac2012, on Flickr DSC02849 by chrismac2012, on Flickr

DSC02849 by chrismac2012, on Flickr DSC02850 by chrismac2012, on Flickr

DSC02850 by chrismac2012, on Flickr DSC02860 by chrismac2012, on Flickr

DSC02860 by chrismac2012, on Flickr DSC02861 by chrismac2012, on Flickr

DSC02861 by chrismac2012, on Flickr Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on Flickr Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on Flickr Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on Flickr Untitled by chrismac2012, on Flickr

Untitled by chrismac2012, on FlickrLast photo already looks pretty awesome Chris!

DSC02864 by chrismac2012, on Flickr

DSC02864 by chrismac2012, on Flickr DSC02866 by chrismac2012, on Flickr

DSC02866 by chrismac2012, on Flickr DSC02867 by chrismac2012, on Flickr

DSC02867 by chrismac2012, on Flickr DSC02868 by chrismac2012, on Flickr

DSC02868 by chrismac2012, on Flickr DSC02870 by chrismac2012, on Flickr

DSC02870 by chrismac2012, on Flickr DSC02871 by chrismac2012, on Flickr

DSC02871 by chrismac2012, on Flickr DSC02872 by chrismac2012, on Flickr

DSC02872 by chrismac2012, on Flickr DSC02874 by chrismac2012, on Flickr

DSC02874 by chrismac2012, on Flickr DSC02875 by chrismac2012, on Flickr

DSC02875 by chrismac2012, on Flickr