You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Increasing width of rear

- Thread starter WillBuc59

- Start date

- Views: 12097

More options

Who Replied?

/ Increasing width of rear

#1

Thomas

Epic Contributor

- Joined

- Apr 6, 2000

- Messages

- 32,021

- Location

- Lebanon,NH.

- Tractor

- Kubota B2650HSD w/Frontloader & CC LTX1046 & Craftman T2200 lawn mower.

Dealer should be able tell you if rear spacers can be added.

newbury

Super Star Member

- Joined

- Jan 8, 2009

- Messages

- 14,852

- Location

- From Vt, in Va, retiring to MS

- Tractor

- Kubota's - B7610, M4700

I increase my rear width with lots of bacon and pancakes. Oh, did you mean tractor rear wheel spacing?

On my M4700 I've got about 5 combos of rim and disc to adjust spacing.

On my M4700 I've got about 5 combos of rim and disc to adjust spacing.

TractorNH

Platinum Member

- Joined

- Apr 11, 2018

- Messages

- 641

- Location

- Southern NH

- Tractor

- Mahindra 2655 HST Cab, Deere 350C Dozer, Case 580CK TLB

Dealer should be able tell you if rear spacers can be added.

Wheel spacers CAN be added though the dealer may not have a source for them. Check out Bro-Tek. You can message Richard (the owner) through their website. They can generally make them for any tractor and they are reasonably priced.

Bro-Tek

Is there a way to increase the rear width for more stability in hilly country? Swapping rear tires?

I searched the forum and didn't come up with anything...

You can move the center hub flange to the inside and gain about 4-6 inches on width.

TomIre

Gold Member

If it helpshelps visualize it, your rear tires can be mounted in different configurations to give you different spacing. Simplest is to look at the rim and see the "dish" in the center. If the dish is on the inside, the rim can be reversed so the dish is on the outside which gives you a good few inches. That's the simplest and cheapest way. Can you take a photo of your rims and post it fit us to look at?

WillBuc59

New member

It looks as if I could swap sides with the tires and gain some width.View attachment 565905View attachment 565906

Are there any reasons NOT to do this?

LouNY

Super Star Member

- Joined

- Jul 4, 2015

- Messages

- 14,555

- Location

- Greenwich, NY

- Tractor

- Branson 8050, IH 574, Oliver 1550 Diesel Utility (traded in on Branson) NH 8160. Kioti CK2620SECH

Are there any reasons NOT to do this?

With your rims if you unbolt the outer section then rotate the inner and move the outer section out you will gain the width of the mounting which is usually 2-4 " on each tire,

which is what posts 4 and 5 mentioned.

If that is not enough adjustment then the rims can be flipped around as they are usually not centered with the mounting tabs.

Providing you with several optional spacings.

IchabodCrayne

Bronze Member

Are there any reasons NOT to do this?

Check your owner's manual. Mine says not to do any of what's been suggested.

Aside from that.. Tractors are designed to carry, push, pull, lift..etc.

Axles, hubs, bearings n such are all designed to carry these loads within specified parameters.

Widening wheel/tire stance moves the applied loads outward on the axles increasing leverage, putting greater stress on vital parts. This means the user must reduce the workload to compensate or live with the expectation of parts failure.

Also note the ROPS is designed to protect you from compete rollover based to some extent on strength vs force applied from tipping point to ground contact. Widening stance increases the force applied to ROPS if tip over occurs due to increased distance from tipping point to ground contact.

TomIre

Gold Member

With your rims if you unbolt the outer section then rotate the inner and move the outer section out you will gain the width of the mounting which is usually 2-4 " on each tire,

which is what posts 4 and 5 mentioned.

If that is not enough adjustment then the rims can be flipped around as they are usually not centered with the mounting tabs.

Providing you with several optional spacings.

What he said! Lots of options before you need to buy anything!

newbury

Super Star Member

- Joined

- Jan 8, 2009

- Messages

- 14,852

- Location

- From Vt, in Va, retiring to MS

- Tractor

- Kubota's - B7610, M4700

Yup, definitely check your owners manual. Also a workshop manual if you can find one.Check your owner's manual. Mine says not to do any of what's been suggested.

<snip>

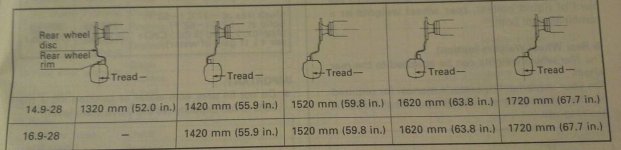

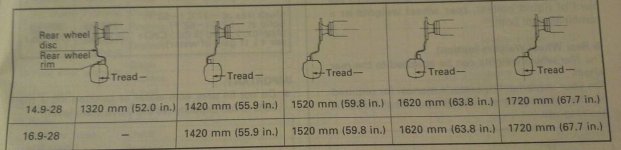

Like the page from my M4700 manual I posted

Where it shows the various stances that can be used.

I'm surprised Ich's manual says not to do any.

Attachments

oosik

Epic Contributor

IchabodCrayne - hard to understand why your owner manual says - "don't do it" - if you have the wheels/rims and can make changes as shown by Newbury - post #13.

However - whether you do or do not have the rims/centers that allow this - the owner manual should be followed.

My M6040 Owners Manual has a diagram just like what Newbury has posted. My rears are filled with 1550 pounds of RimGuard. Thank goodness they are out there at the widest setting. I certainly could not handle the tires being they are filled.

I had filled tires on my first tractor - 26hp Ford 1710. I changed the center/rim configuration by myself and almost got the snot crushed outta me when the tire decided to lay down - - on me. Thank God - that was 35 years ago when I was somewhat quick and nimble. Now-a-days - - I'd probably just lie there - bellow and rot away. Ha, ha, ha Become coyote food.

However - whether you do or do not have the rims/centers that allow this - the owner manual should be followed.

My M6040 Owners Manual has a diagram just like what Newbury has posted. My rears are filled with 1550 pounds of RimGuard. Thank goodness they are out there at the widest setting. I certainly could not handle the tires being they are filled.

I had filled tires on my first tractor - 26hp Ford 1710. I changed the center/rim configuration by myself and almost got the snot crushed outta me when the tire decided to lay down - - on me. Thank God - that was 35 years ago when I was somewhat quick and nimble. Now-a-days - - I'd probably just lie there - bellow and rot away. Ha, ha, ha Become coyote food.

IchabodCrayne

Bronze Member

Texasmark

Elite Member

- Joined

- Apr 24, 2012

- Messages

- 3,766

- Location

- N. Texas

- Tractor

- Ford: '88 3910 Series II, '80 3600, '65 3000; '07 6530C Branson with FEL, 2020 LS MT225S. Case-IH 395 and 895 with cab. All Diesels

This worked for me on my 2400:

The spacer is a piece of 8" dia x 4" wide steel pipe welded onto a couple of flanges made from a piece of 0.25 inch steel plate. I took the plate to a local machine shop with a machine drawing I made of the mounting interface and had them cut out 4 adapter plates. The OEM bolts bolted the spacers to the axle hub (through the hole I deliberately left in the center) and the hardware store supplied the wheel to adapter hardware. Total cost about a hundred bucks for everything.

The width of 4" brought my outer rear tire width to be even with my 5', 3 pt. rotary mower.....could have been wider if I was doing it solely for stability purposes. Guarantee you this. 4" per side does matter.

Edit:

When you assemble (weld up) the units, ensure that you line up the holes in a straight line. To mount to the tractor hub, insert the bolts and the socket through the center hole and come through the outer stud mounting hole with the socket wrench extension for tightening.

Putting the wheel on the assy is obvious.....you can see a backing nut in the left picture.

The spacer is a piece of 8" dia x 4" wide steel pipe welded onto a couple of flanges made from a piece of 0.25 inch steel plate. I took the plate to a local machine shop with a machine drawing I made of the mounting interface and had them cut out 4 adapter plates. The OEM bolts bolted the spacers to the axle hub (through the hole I deliberately left in the center) and the hardware store supplied the wheel to adapter hardware. Total cost about a hundred bucks for everything.

The width of 4" brought my outer rear tire width to be even with my 5', 3 pt. rotary mower.....could have been wider if I was doing it solely for stability purposes. Guarantee you this. 4" per side does matter.

Edit:

When you assemble (weld up) the units, ensure that you line up the holes in a straight line. To mount to the tractor hub, insert the bolts and the socket through the center hole and come through the outer stud mounting hole with the socket wrench extension for tightening.

Putting the wheel on the assy is obvious.....you can see a backing nut in the left picture.

Attachments

Gale Hawkins

Super Star Member

- Joined

- Sep 20, 2009

- Messages

- 12,426

- Location

- Murray, KY

- Tractor

- 1948 Allis Chambers Model B 1976 265 MF / 1983 JD 310B Backhoe / 1966 Ford 3000 Diesel / 1980 3600 Diesel

I expect someone bought a lawsuit after snapping an axle, etc. We just picked up a used 14K pound rate tilt trailer in part to get 82" between fenders since all three tractors are set up at 70 % of max width. I need all of the stability that I can get.Yup, definitely check your owners manual. Also a workshop manual if you can find one.

Like the page from my M4700 manual I posted

Where it shows the various stances that can be used.

I'm surprised Ich's manual says not to do any.

FastEddieR

Bronze Member

This is a Branson forum, your tractor is a Kubota...different manufacturers, different specifications.

Texasmark

Elite Member

- Joined

- Apr 24, 2012

- Messages

- 3,766

- Location

- N. Texas

- Tractor

- Ford: '88 3910 Series II, '80 3600, '65 3000; '07 6530C Branson with FEL, 2020 LS MT225S. Case-IH 395 and 895 with cab. All Diesels

Check your owner's manual. Mine says not to do any of what's been suggested.

Aside from that.. Tractors are designed to carry, push, pull, lift..etc.

Axles, hubs, bearings n such are all designed to carry these loads within specified parameters.

Widening wheel/tire stance moves the applied loads outward on the axles increasing leverage, putting greater stress on vital parts. This means the user must reduce the workload to compensate or live with the expectation of parts failure.

Also note the ROPS is designed to protect you from compete rollover based to some extent on strength vs force applied from tipping point to ground contact. Widening stance increases the force applied to ROPS if tip over occurs due to increased distance from tipping point to ground contact.

Good thoughts but I have other thoughts.

OEMs have wheels made specifically for adjusting tread width to suit the application and wheel weights specifically designed for wheels to increase weight and improve traction on both front and rear tires or if not on front tires, on a rack on the front of the tractor. Common sense lends itself to a 6 ply tire of a size to suit the tractor, pumped up to 18 psig., max rating for a lot of F1s vs a steel axle of appropriate dimensions would be a no contest on who wins.

Any time somebody tells me don't do something, if they don't tell me why so that I can make up my own mind as to whether or not my application meets or even exceeds the requirements of the DON'T then it doesn't apply to me. Merely to say don't do something and not explain it is pure BS.

On the ROPS thing, I have a cab and rops on the 2400 and 3910. Doesn't take a rocket scientist to look at the materials chosen for the job and assembly method to see that to damage the rops to any extent one would have to drive the tractor off a cliff. Actually, by increasing the stability of the machine the need for the ROPS in the first place is negated to that extent.

Cougsfan

Veteran Member

- Joined

- Sep 10, 2008

- Messages

- 1,651

- Location

- Eastern Washington State

- Tractor

- Ferguson TO35, Branson 4720CH

Are there any reasons NOT to do this?

The only reason I can think of why you may not wish to add to your rear tread width: Particularly using box blades and mowers it is very desirable to have the implement wider than the tread width so your implement will cover your tracks and so you can get closer to the edge of whatever real estate you are grooming.