npalen

Elite Member

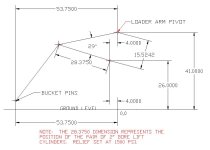

I was curious what the relief valve setting should be on my Kubota BF350 front end loader (FEL). So I did the attached layout based on measurements taken.

I come up with a theoretical lift force at the bucket pins (excluding friction and weight of loader itself) of 2,720 lbs.

The owners manual for the Kubota B9200 shows a loader lift capacity of 838 pounds at 1636 psi relief setting. (Discovered this data after using estimated 1500 psi)

So I'm needing help understanding where the discrepancy is occurring between the 2,720 pounds and 838 pounds.

Here are my calculations: 2" cylinder bore equals 3.14 sq. in. piston area times two cylinders = 6.28

1500 psi times 6.28 =9420 pounds force

9420 lbs. times 15.524" lever arm = 146,236 in. lbs torque about loader arm pivot point.

146,236 divided by 53.750 lever arm from bucket pins to loader arm pivot pins = 2720 lift force at bucket pins

Anyone care to check the math for me?

I come up with a theoretical lift force at the bucket pins (excluding friction and weight of loader itself) of 2,720 lbs.

The owners manual for the Kubota B9200 shows a loader lift capacity of 838 pounds at 1636 psi relief setting. (Discovered this data after using estimated 1500 psi)

So I'm needing help understanding where the discrepancy is occurring between the 2,720 pounds and 838 pounds.

Here are my calculations: 2" cylinder bore equals 3.14 sq. in. piston area times two cylinders = 6.28

1500 psi times 6.28 =9420 pounds force

9420 lbs. times 15.524" lever arm = 146,236 in. lbs torque about loader arm pivot point.

146,236 divided by 53.750 lever arm from bucket pins to loader arm pivot pins = 2720 lift force at bucket pins

Anyone care to check the math for me?