HeLa

Gold Member

i did a good bit of research on this last year.

fusion is best practice. and everything i read suggested that this should be done by an experienced professional. set up all your joints, call someone in, cost should be reasonable.

that said - i went with barbs and clamps because i was doing the work a little at a time and it wasn't practical to call someone in (or even rent the tool) each time.

if you go with barbed fittings, a few tips from my experience:

1. i used heavy poly (250 psi ?) warmed in hot water or sun (avoided a heat gun for fear of warping plastic) and tapped the barbs in with rubber mallet where possible

2. lead-free brass fittings with extra long barbs

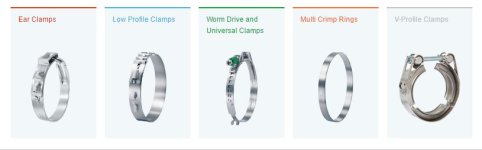

3. double clamped every barb with stainless oetiker clamps. (don't waste your time/money with the screwclamp junk)

4. spend a few extra bucks on the oetiker crimp tool that can grab the ears parallel or perpendicular

fusion is best practice. and everything i read suggested that this should be done by an experienced professional. set up all your joints, call someone in, cost should be reasonable.

that said - i went with barbs and clamps because i was doing the work a little at a time and it wasn't practical to call someone in (or even rent the tool) each time.

if you go with barbed fittings, a few tips from my experience:

1. i used heavy poly (250 psi ?) warmed in hot water or sun (avoided a heat gun for fear of warping plastic) and tapped the barbs in with rubber mallet where possible

2. lead-free brass fittings with extra long barbs

3. double clamped every barb with stainless oetiker clamps. (don't waste your time/money with the screwclamp junk)

4. spend a few extra bucks on the oetiker crimp tool that can grab the ears parallel or perpendicular