davrow

Veteran Member

I'm going to fill my tires, just bought the adapter tool (don't have it yet... Amazon)

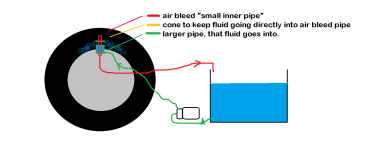

Most of the posts I've read over time and just now doing a search mention having to bleed air. The tool wants you to stop pumping to bleed... seems like a waste of time.

How bad to the rim/tire would it be to install a second valve (tubeless, of course) so you could fill (or drain) through one while the other acts as the air bleed? They would have to be close together so always having one at a more convenient position for normal airing up wouldn't be possible.

I realize this would double your chances of knocking a valve stem off by hitting a branch or something, also of getting a valve stem air leak. What other pros or cons might there be?

What are your thoughts?

Most of the posts I've read over time and just now doing a search mention having to bleed air. The tool wants you to stop pumping to bleed... seems like a waste of time.

How bad to the rim/tire would it be to install a second valve (tubeless, of course) so you could fill (or drain) through one while the other acts as the air bleed? They would have to be close together so always having one at a more convenient position for normal airing up wouldn't be possible.

I realize this would double your chances of knocking a valve stem off by hitting a branch or something, also of getting a valve stem air leak. What other pros or cons might there be?

What are your thoughts?