284 International

Veteran Member

- Joined

- Jun 28, 2010

- Messages

- 1,464

- Tractor

- International Harvester 284

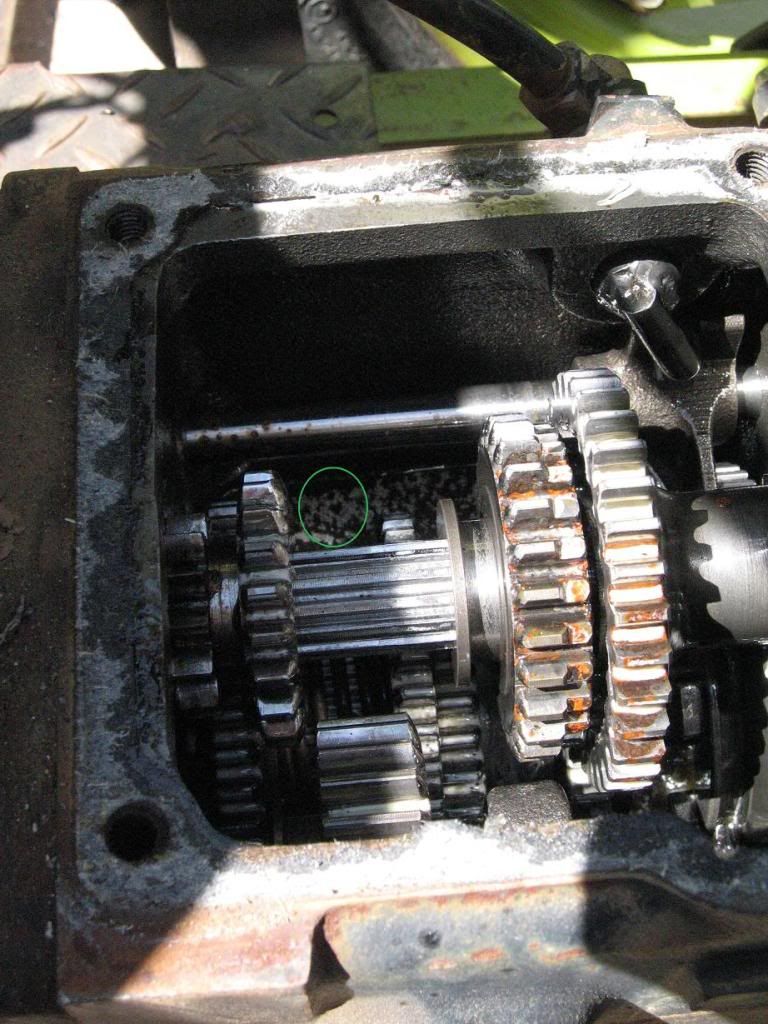

Are there any tricks to removing the transmission cover on a YM2000? (Part 16)

I've pulled this part on my YM240 before, and it came off with 4 bolts. This time, it seems to be immovable. It has been immune to a dead blow hammer, blocks of wood walloped with a regular hammer, a putty knife hammered between the transmission case and the cover, hooks slid inside and levered upward with a 2x4, and probably some other methods I'm forgetting.

The tractor has lost neutral and reverse. That is, in those positions, the tractor moves forward when the clutch is let out. None of the other shifter positions correspond to anything other than forward, or locked. I'm suspicious of the shifter forks, but can't pull the cover off. I'm ready to build some hooks to connect onto my engine hoist, but I really don't want to break this cover.

The shifter cover (Part 8 (I guess) here) comes off easily; everything appears intact, movable, with functioning detents and so forth.

I haven't tried the old heat wrench yet; maybe tomorrow will bring me to that.

It's weird. There's going to be some write-ups about this coming, I suspect.

I've pulled this part on my YM240 before, and it came off with 4 bolts. This time, it seems to be immovable. It has been immune to a dead blow hammer, blocks of wood walloped with a regular hammer, a putty knife hammered between the transmission case and the cover, hooks slid inside and levered upward with a 2x4, and probably some other methods I'm forgetting.

The tractor has lost neutral and reverse. That is, in those positions, the tractor moves forward when the clutch is let out. None of the other shifter positions correspond to anything other than forward, or locked. I'm suspicious of the shifter forks, but can't pull the cover off. I'm ready to build some hooks to connect onto my engine hoist, but I really don't want to break this cover.

The shifter cover (Part 8 (I guess) here) comes off easily; everything appears intact, movable, with functioning detents and so forth.

I haven't tried the old heat wrench yet; maybe tomorrow will bring me to that.

It's weird. There's going to be some write-ups about this coming, I suspect.