rhamer

Silver Member

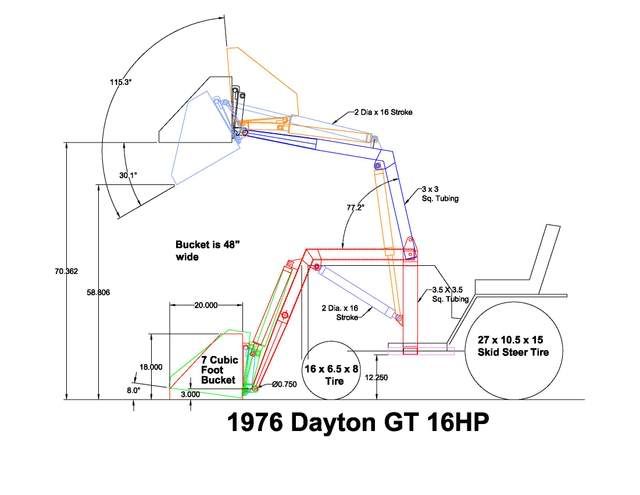

In designing my home built loader for my tractor, I noticed that most loader arms are tapered.

Does anybody know why?

The only thing I can come up with is it makes the connection points easier to manufacture as the swivel point is narrower.

I intend to do the same thing, if only to make it look right, but I would like to know why they do it.

Cheers

Rohan

Does anybody know why?

The only thing I can come up with is it makes the connection points easier to manufacture as the swivel point is narrower.

I intend to do the same thing, if only to make it look right, but I would like to know why they do it.

Cheers

Rohan