flingwing1969

Platinum Member

- Joined

- Jun 2, 2008

- Messages

- 692

- Tractor

- LS G3038, JD GT275, and Bolins H16

About two years ago, I had two slabs poured for two 20 x 24 metal shops with 9-foot walls. I ordered the metal and got going on the shops this summer, got one frame up by myself and my brother-in-law came over and helped me get one and 2/3 of the 24' side walls up before he decided that was way too much like work and I never saw him again.

I then came down with a bad recurrence of vertigo that has plagued me off and on since my service days and that kept me off the roof and off ladders, and it is still with me a bit since August now. Anyway, I'm going to get started on finishing the shop soon but 24' long pieces of 5-rib is like handling wet spaghetti, takes two to carry it and really three to lift it onto the sidewall to tack it down (if you don't want it to bend and crease).

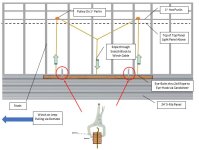

So I was thinking, how can I stiffen these panels (that are not heavy, really) so one guy can carry it to the shed and then, how do I get the bloody thing up the wall so I can tack it in place. Well, this is what I've come up with - haven't tried it but I don't see why it won't work.

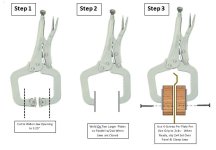

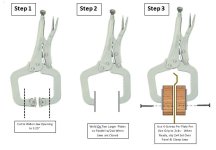

1. I create a stiffened edge with two 10' 2x4s sandwiching the tin just below the top rib using my handy dandy modified vice-grip welding pliers,

2. That way, only 7' of tin is unsupported on each end and this length is stiff enough to support itself without bending

3. I can then carry it to the wall.

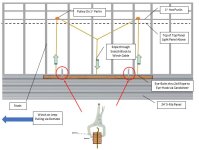

4. I lean it against the wall and connect a rope tied to a carabiner to eye-bolts on each end of the 2x4s, and

5. Lift it up the wall with my Jeep's winch via a system of pulleys and a snatch block.

6. Climb onto my scaffold and screw the panel down

7. Remove the carabiners and repeat with the next panel.

If anyone has any possible use for this, feel free to steal it. If you see any flaws in my plan, let me know.

I then came down with a bad recurrence of vertigo that has plagued me off and on since my service days and that kept me off the roof and off ladders, and it is still with me a bit since August now. Anyway, I'm going to get started on finishing the shop soon but 24' long pieces of 5-rib is like handling wet spaghetti, takes two to carry it and really three to lift it onto the sidewall to tack it down (if you don't want it to bend and crease).

So I was thinking, how can I stiffen these panels (that are not heavy, really) so one guy can carry it to the shed and then, how do I get the bloody thing up the wall so I can tack it in place. Well, this is what I've come up with - haven't tried it but I don't see why it won't work.

1. I create a stiffened edge with two 10' 2x4s sandwiching the tin just below the top rib using my handy dandy modified vice-grip welding pliers,

2. That way, only 7' of tin is unsupported on each end and this length is stiff enough to support itself without bending

3. I can then carry it to the wall.

4. I lean it against the wall and connect a rope tied to a carabiner to eye-bolts on each end of the 2x4s, and

5. Lift it up the wall with my Jeep's winch via a system of pulleys and a snatch block.

6. Climb onto my scaffold and screw the panel down

7. Remove the carabiners and repeat with the next panel.

If anyone has any possible use for this, feel free to steal it. If you see any flaws in my plan, let me know.