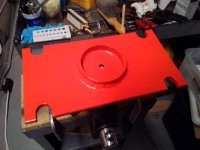

Machining of the plate and ring are done. I made a 1/4" thick disk out of aluminum with a 1/4-20 hole in the center to hold the ring in place while tack welding. Disk will get removed before final welding. 1/4" hole in the plate can serve as a hanging hole for going on the pegboard, but being centered, the part may want to choose its own random orientation. I may add another 1/4" hole closer to one of the ends...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

what are the four holes for in the bottom of the TO-30 differential case?

- Thread starter dbotos

- Start date

- Views: 21175

/ what are the four holes for in the bottom of the TO-30 differential case?

#41

The kid

Elite Member

- Joined

- Apr 25, 2012

- Messages

- 3,886

- Location

- Middle Tennessee

- Tractor

- 1965 135 gasser, 1967 135 diesel

What's it for?Welded and painted. Now I can finally use the darn thing.

The kid

Elite Member

- Joined

- Apr 25, 2012

- Messages

- 3,886

- Location

- Middle Tennessee

- Tractor

- 1965 135 gasser, 1967 135 diesel

That what mine it used for. Handy pulling a trailer. Two bolts dropped in either side to keep the bar stationary. It would be a real pain to swap it just to put it back on. Cribbing and a car jack and I can put all four wheels on blocks in about twenty minutes. I positioned mine like a tripod. Two jacks on the rear axel and one up front at a solid point behind the front pivot. Cribbed the front pivot after i had it in the air. Piece of cake. I bought a Harbour Frieght 1000# impact that will deal with most any frozen nut. Drum screws are a bit more tricky. Gotta have my draw bar though.I think it for use with a swinging draw bar if I'm not mistaken.

The kid

Elite Member

- Joined

- Apr 25, 2012

- Messages

- 3,886

- Location

- Middle Tennessee

- Tractor

- 1965 135 gasser, 1967 135 diesel

I used a regular hydraulic car jack which has a pretty good sized foot on it to lift one side to crib and a jack stand. Do the same to other. By lifting the entire rearend you already know about what happens to the front. That is why I tripod mine when I pulled all the wheels off. Good luck.Keeping the head of the bottle jack centered on the bottom of the diff.

I used a regular hydraulic car jack which has a pretty good sized foot on it to lift one side to crib and a jack stand. Do the same to other. By lifting the entire rearend you already know about what happens to the front. That is why I tripod mine when I pulled all the wheels off. Good luck.

I will have to keep that in mind depending on how well the front axle blocking works.

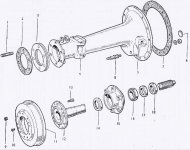

Okay, so from what I can garner, the seal that goes in the outboard end of the trumpet is the inner axle seal (2" ID) (find #18). The outer seal (2.375" ID) (find #14) is on the other side of that bolt-on bearing retainer casting (find #15). Bearing is find #16 and find #17 is a shrink-fit collar that keeps everything between it and the flange of the axle trapped on there. Inner seal looks straightforward to replace. Any tips for the outer? The service manual talks about drilling and splitting the shrink fit collar and then shows multiple images of a special hydraulic puller/press...