You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weld critique please

- Thread starter Cord

- Start date

- Views: 4218

More options

Who Replied?

/ Weld critique please

#1

Shield Arc

Super Member

Are you on the correct polarity, for that wire?

How much stick out, are you welding with?

How much stick out, are you welding with?

Shield Arc

Super Member

I generally run about 3/8" to 7/16" stick out. I think your running to much gas. I never heard of that wire. So I looked it up. I don't know how to convert that to CFPH.

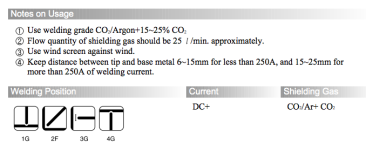

http://www2.hyundaiwelding.com/jp/product/eng_welding/pdf/SM-70.pdf

http://www2.hyundaiwelding.com/jp/product/eng_welding/pdf/SM-70.pdf

I generally run about 3/8" to 7/16" stick out. I think your running to much gas. I never heard of that wire. So I looked it up. I don't know how to convert that to CFPH.

http://www2.hyundaiwelding.com/jp/product/eng_welding/pdf/SM-70.pdf

It works out to be just over 50cfh so I might be low. I should say that I also tried CO2 with simular results. I tried a short stick out and got a very ugly weld.

Shield Arc

Super Member

WOW! That seems very high to me. But Like I said, I never heard of that wire. With C-25 I run about 15-18-cfh.

Your fillet weld, the plates don't look to bad, but the flat plate, I would clean better.

You may try turning the voltage down some too. Without being there to hear the weld, hard for me to help much.

Your fillet weld, the plates don't look to bad, but the flat plate, I would clean better.

You may try turning the voltage down some too. Without being there to hear the weld, hard for me to help much.

MinnesotaDaveChalmers

Platinum Member

I'm confused by 400ipm at 105 amps. Those numbers don't appear to agree.

What wire size?

The chart link does not list 90/10 as a recommended gas.

What wire size?

The chart link does not list 90/10 as a recommended gas.

LD1

Epic Contributor

Not familiar with the amps setting either. I'm no pro, but have welded with many welders. Never an amp setting. Only voltage and wire speed. For 300ipm, should like somewhere between 21-24v for short circuit welding with most of the machines I'm familiar with.

Flat plate is too rusty. Might likes clean.

And agree, 35cfh is a waste of gas. 15-20 is usually plenty. So the gas maybe your issue, if it isn't, it's just wasting gas.

Flat plate is too rusty. Might likes clean.

And agree, 35cfh is a waste of gas. 15-20 is usually plenty. So the gas maybe your issue, if it isn't, it's just wasting gas.

Gary Fowler

Super Star Member

- Joined

- Jun 23, 2008

- Messages

- 11,998

- Location

- Bismarck Arkansas

- Tractor

- 2009 Kubota RTV 900, 2009 Kubota B26 TLB & 2010 model LS P7010

I am not a MIG expert by no means, but 50 CFH is way to high and could be the cause for the rough weld. Think white capping on a lake from high winds which is what you are doing to the weld puddle with that kind of gas flow.

The porosity is for sure caused by all the rust you are welding over. You have to clean rust completely before welding as just a small speck will cause porosity and lots of it. I am a champion of cleaning the weld area of all contaminates prior to striking the first arc regardless of the process used. Lots of hobby welders think stick rod with a 6010 /6011 rod doesn't require cleaning but that is not the case. You may get by a little more by not cleaning with stick rod, but you will suffer the pain of more sparks, some porosity. ugly welds and generally harder to make tie ins when the metal is dirty. The few minutes spent cleaning the weld area will pay dividends in ease of welding and better quality welds.

SO lower your gas flow to 15-20 CFH, clean the rust completely first then you can work on setting the machine a little better.

The porosity is for sure caused by all the rust you are welding over. You have to clean rust completely before welding as just a small speck will cause porosity and lots of it. I am a champion of cleaning the weld area of all contaminates prior to striking the first arc regardless of the process used. Lots of hobby welders think stick rod with a 6010 /6011 rod doesn't require cleaning but that is not the case. You may get by a little more by not cleaning with stick rod, but you will suffer the pain of more sparks, some porosity. ugly welds and generally harder to make tie ins when the metal is dirty. The few minutes spent cleaning the weld area will pay dividends in ease of welding and better quality welds.

SO lower your gas flow to 15-20 CFH, clean the rust completely first then you can work on setting the machine a little better.

MinnesotaDaveChalmers

Platinum Member

Well, I fiddled with the setup a bit more and got it to lay a decent bead. Still don't like the porosity at the puddle.

In the end, I guess it doesn't matter. Shortly after that picture was taken something went awry with the welder. During a weld the amperage would drop off until the arc collapsed. Got on the phone with the mfr and they're going to warranty the machine. Sigh.

In the end, I guess it doesn't matter. Shortly after that picture was taken something went awry with the welder. During a weld the amperage would drop off until the arc collapsed. Got on the phone with the mfr and they're going to warranty the machine. Sigh.

Attachments

PJSprog

Elite Member

Your mother was a hamster and your father smelt of elderberries.

Oh...wait...you said critique the weld, not welder...never mind

You can never go wrong with a Python quote. Ever.

LD1

Epic Contributor

Did you ever say what make / model the welder is? I assume new since they are going to warranty it

yomax4

Elite Member

- Joined

- Mar 11, 2007

- Messages

- 2,858

- Location

- Midwest

- Tractor

- ISEKI TA 247. Stihl Saws Gravely Zt's Polaris ATV's State Of The Art Welding Equipment

Porosity is nearly always a gas issue. Gun angle could be a slim part of it but check to see that you are really getting at least 15cfh at the weld. You may have a bad o-ring or a loose gun.

muddstopper

Veteran Member

I once had a similar problem with my mig. I had installed a new liner and everything was going fine for a while. Then the weld just got ugly. porosity, splatter, wire burning back to the nozzle. Turns out I had left the bolt lose where the cable plugs into the wire feeder and the cable has pushed part way out of its connection. Gas was leaking out at the connection instead of flowing thru to the nozzle. Took me a while to figure out the problem but once I push the cable back in place and tighten the thumb screw it ran a lot better.

TMGT

Elite Member

I thought I had a bad tank of argon on my tig for awhile, drove me nuts, changed the tank and still had problems. Was replacing the regulator and found a barely lose connection for the adaptor for hose off the regulator, was pulling atmosphere into the shielding gas. I'd go back and check all connections, also can be a bad regulator.