So I need to install some guy wires into a concrete block with wedge anchors.. They are rated at 10,000+ pounds tension. Obviously I want the best attachment.

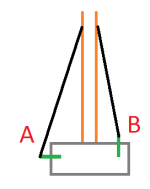

Would it be better to install them in the side of the concrete block instead of the top surface? See pic..

I know they are designed to be mounted a "B" shows. But would mounting them on the side as "A" shows be beneficial?

My initial hunch is side mounting "A" might cause cracks in the crete easier. But if it doesn't, it may provide greater attachment point.

Any feedback?

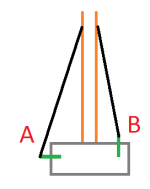

Would it be better to install them in the side of the concrete block instead of the top surface? See pic..

I know they are designed to be mounted a "B" shows. But would mounting them on the side as "A" shows be beneficial?

My initial hunch is side mounting "A" might cause cracks in the crete easier. But if it doesn't, it may provide greater attachment point.

Any feedback?