MF243RedTop

Gold Member

Picked up a vertical band saw off FB marketplace dirt cheap... It was listed as a meat saw. I've spent most of my adult life in the processing of meat. Used larger commercial hobart saws, this is nothing like that.

The wheels are 20" in diameter flat on top. Look to be about an inch wide or so..They also have a "for lack of better terms" a square key groove way cut around the perimeter of the wheel down the middle of the flat top, maybe a 1/16 wide not very deep.. I have not idea about that .

the guy said it originally had a 3 phase motor in it, converted now to 110..not too concerned about the electric motor, it does work but I'm probably converting to a gas engine sooner or later..

The frame is 3" tubing 3/16 thick.

The vertical tubing that supports the top wheel looks to be about 3x5" tubing 3/16 thick. I'm 6'4" and it's a little taller than myself.

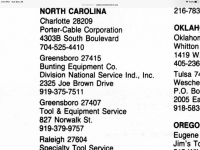

Only identification plate was

"Bunting Equipment Company" Greensboro NC, with a serial number that I could get basically nothing from on Google..

I'm mainly interested in what the rpm/load rating is on the saw and wheels... I'm in the beginning stages, I thinking of converting it to a horizontal mill.. little concerned about the weight of the band and vertical tubing now..once I seperate it from the frame.. wasn't counting on that 3x5 tubing..

I'm think it's probably some type of industrial manufacturing band saw...from what little I could source on its size

Thanks Brian

The wheels are 20" in diameter flat on top. Look to be about an inch wide or so..They also have a "for lack of better terms" a square key groove way cut around the perimeter of the wheel down the middle of the flat top, maybe a 1/16 wide not very deep.. I have not idea about that .

the guy said it originally had a 3 phase motor in it, converted now to 110..not too concerned about the electric motor, it does work but I'm probably converting to a gas engine sooner or later..

The frame is 3" tubing 3/16 thick.

The vertical tubing that supports the top wheel looks to be about 3x5" tubing 3/16 thick. I'm 6'4" and it's a little taller than myself.

Only identification plate was

"Bunting Equipment Company" Greensboro NC, with a serial number that I could get basically nothing from on Google..

I'm mainly interested in what the rpm/load rating is on the saw and wheels... I'm in the beginning stages, I thinking of converting it to a horizontal mill.. little concerned about the weight of the band and vertical tubing now..once I seperate it from the frame.. wasn't counting on that 3x5 tubing..

I'm think it's probably some type of industrial manufacturing band saw...from what little I could source on its size

Thanks Brian

Last edited: