I'm getting ready to weld up my backhoe ripper with an old AC buzzbox. The shank is 1" and the top plate that attaches it to the ears is 1/2".

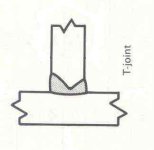

I am trying to figure out how big to make my bevels in the 1" shank for the t joint. I looked online and saw 1/4" as a recommended bead size. You can see pictures of it here:

http://www.tractorbynet.com/forums/build-yourself/220577-john-deere-260-backhoe-ripper.html

Do you have any suggestions for the amps setting on the welder? It's 220VAC.

I am trying to figure out how big to make my bevels in the 1" shank for the t joint. I looked online and saw 1/4" as a recommended bead size. You can see pictures of it here:

http://www.tractorbynet.com/forums/build-yourself/220577-john-deere-260-backhoe-ripper.html

Do you have any suggestions for the amps setting on the welder? It's 220VAC.