I think bale spears are the least expensive high-strength forks unless you can get a deal on something at a scrap yard.

Agri Supply - Search Results for spear

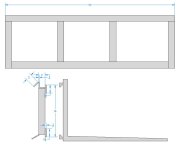

The lift capacity of forklilfts is typically more than 3x the capacity of a CUT loader. You don't necessarily need that much strength but real forks are nice for their thinness, taper, and durability.

Here are the ones at Northern - note the 4000lb capacity and the price tag.

Atlas Forklift Forks — 4,000-Lbs., 42 in. | Replacement Forks | Northern Tool + Equipment

To calculate the point load at the tip of a fork that will cause the metal to yield,

Load = (yield strength)*(width)*(thickness squared)/(6*(length))

If you were to make a fork out of 4"x1.5" x 48" hot-rolled mild steel with a yield stress of 36,300psi, the end load at yield is 1134lb. Actually you have to subtract half of the 82lb weight of the fork from that value which brings it to about 1093lb. By the way, a new piece of steel that size will cost a lot more than a bale spear.

Edit - I was away for a while in the middle of this response - didn't notice your clarification. For the frame, mild steel should be fine but if higher strength is available at a reasonable price go for it. I tend to use whatever I can get for scrap price or less.