ptsg

Super Member

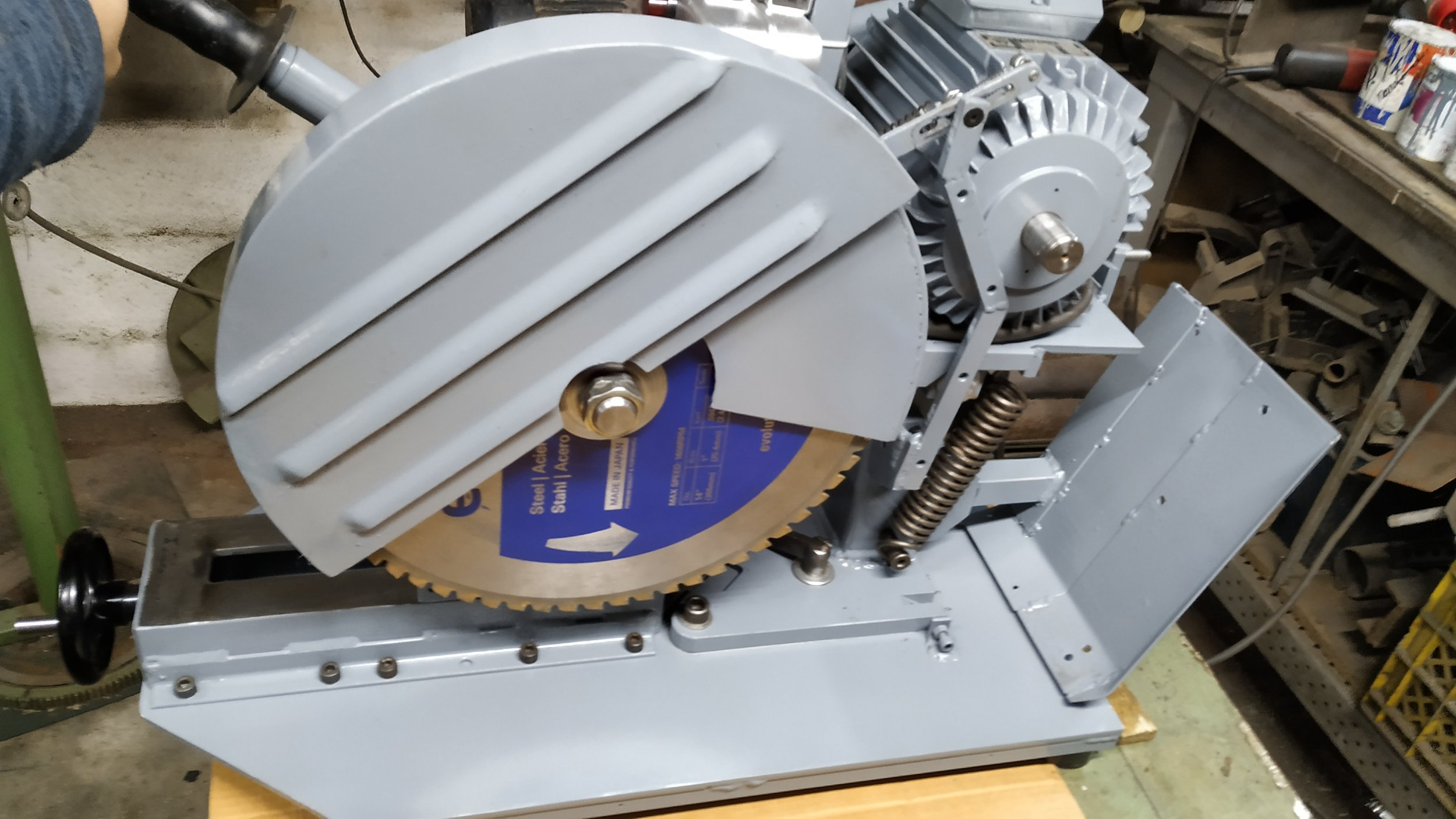

I built one from scratch using an Evolution 14" saw blade, including the vise. Cuts very nicely or used to until I pulled a dumb move and ruined the blade. On mine, I made it so the entire head rotates from 0 to 45 degree by simply loosening a lever, rotate the head and tight it back on. It has a 1.5 HP 3 phase electric motor.

It's a bit noisy and throws stuff everywhere but cuts indeed very well. If I were to build another one, I would have used a band saw blade instead of a circular saw blade.

It's a bit noisy and throws stuff everywhere but cuts indeed very well. If I were to build another one, I would have used a band saw blade instead of a circular saw blade.