stuartmcraycattle

New member

- Joined

- Jan 29, 2012

- Messages

- 15

- Tractor

- Case JX75

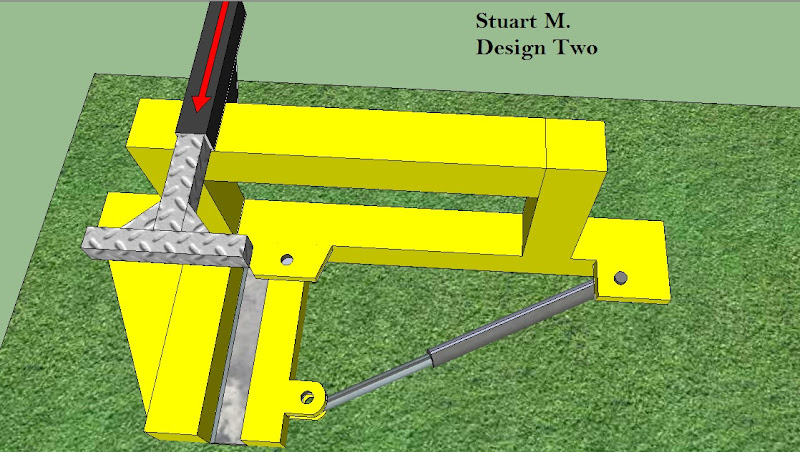

Well I am fairly new here but I would like to have the creative and practical minds help with my design ( hopefully cutting costs). My initial design I drew up tonight is below...The main frame I already possess is 4" square framework from a heavy duty hay fork setup that I have remove the forks...I plan on using mostly .25 sheet for reinforcing and .375 wall box tubing for everything else. the upper grey bar I figure would rest against taller trees to help push them forward away from my tractor... I know I will have to add some bracing at the cylinder mounting points but the drafting program was tough to draw them but I really would like the thoughts on any major points I may be missing...Plan on starting this weekend and I will keep you all up to date...