sacu

New member

Last year my 10+ yrs old Harbor Freight 15k pto generator started leaking oil. The only thing I could say was “It had to be the inner pto seal”. Not knowing to much about these things I figured 3 things could happen. I could buy a new one, try to fix it, or try to fix it breaking it and then buy a new one.

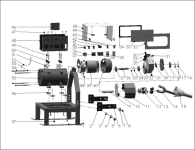

Let’s start by saying the manual and the parts diagram are total crap. Getting parts from Harbor Freight has been terrible and I’m still waiting for parts I order 6 months ago but the seals are on Ebay. So here's my not so professional recommendation of how to do it with some pics for clarity.

Drain the pto oil.

Remove the 4 bolts and remove the louvered end cover.

I would recommend removing the 2 bolts (image 2) that hold the brushes in part and moving them out of the way, I didn’t do this and broke the plastic mount piece and had to fabricate a new piece because my rotor and bearings pulled out with the pto gear box, (image 0).

There is a large bolt running through the rotor shaft remove it (image 2). This is what holds the rotor to the pto gear box. It’s just a taper fit on the end of the shaft (image 4). Hint: You could damage your brushes if you don’t and also pull out the whole rotor J.

Brace the generator up and remove the 2 fwd mounts

Remove the 4 bolts that hold the generator ends to the stator housing.

Carefully remove the front generator end with the pto gear box. The generator end is soft cast aluminum and dents very easily if you use a persuader “ aka: hammer “. Once off you know have access to the inner oil seal (image3). Mine was very badly dry rotted and cracked (image 1).

I choose not to remove the generator end from the pto gear box because I was worried about an alignment issues getting it back together. Hope this helps someone out there.

Let’s start by saying the manual and the parts diagram are total crap. Getting parts from Harbor Freight has been terrible and I’m still waiting for parts I order 6 months ago but the seals are on Ebay. So here's my not so professional recommendation of how to do it with some pics for clarity.

Drain the pto oil.

Remove the 4 bolts and remove the louvered end cover.

I would recommend removing the 2 bolts (image 2) that hold the brushes in part and moving them out of the way, I didn’t do this and broke the plastic mount piece and had to fabricate a new piece because my rotor and bearings pulled out with the pto gear box, (image 0).

There is a large bolt running through the rotor shaft remove it (image 2). This is what holds the rotor to the pto gear box. It’s just a taper fit on the end of the shaft (image 4). Hint: You could damage your brushes if you don’t and also pull out the whole rotor J.

Brace the generator up and remove the 2 fwd mounts

Remove the 4 bolts that hold the generator ends to the stator housing.

Carefully remove the front generator end with the pto gear box. The generator end is soft cast aluminum and dents very easily if you use a persuader “ aka: hammer “. Once off you know have access to the inner oil seal (image3). Mine was very badly dry rotted and cracked (image 1).

I choose not to remove the generator end from the pto gear box because I was worried about an alignment issues getting it back together. Hope this helps someone out there.