FTG-05

Elite Member

- Joined

- Jan 7, 2011

- Messages

- 2,574

- Location

- TN

- Tractor

- Kubota L4330 GST w/FEL, Kubota RTV-XG850, Kubota ZD326S

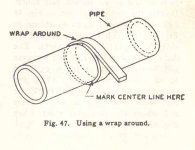

I have this piece of pipe, roughly the size of a 55 gallon barrel that was rough-cut with a torch. I need to square the ends off so I can design and build my shop wood stove.

Although it can't be seen in the pics below, there is about an inch or 1 1/4" gap on one end, I believe that's about the worse part.

The piece is about a 1/4" thick and weighs 75-100 lbs. I have a grinder, abrasive saw, bandsaw and air grinder/cutoff tool. No torch or plasma cutter (I wish).

Any ideas for squaring this off?

Thanks,

Although it can't be seen in the pics below, there is about an inch or 1 1/4" gap on one end, I believe that's about the worse part.

The piece is about a 1/4" thick and weighs 75-100 lbs. I have a grinder, abrasive saw, bandsaw and air grinder/cutoff tool. No torch or plasma cutter (I wish).

Any ideas for squaring this off?

Thanks,