Eddie,

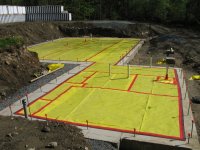

Thanks for your kind words. COST STANDPOINT: I found it was 15-20% higher vs. having the exterior walls 2X6 stick built + adding closed cell foam between studs, sheathing, etc, again just on the Exterior Walls. Just to ensure I was making a sound decision I gathered (5) bids in each category, Stick vs. ICF. Higher Cost Driver: Exterior James Hardie Lap Siding Installation Labor - After reading lots of material and reviewing blogs I settled on having it screwed into the ICF Web every 12", that's a good chunk of change rather than a sub zooming along shooting it on with a nailer over the sheathing. I can't think of any other cost drivers since the ICF Blocks only affect the exterior walls. Once the Drywall Sub understood the embedded web spacing @ 6" and how that was identified on the Build Block Product, he commented it was easier than installing over a 16 OC studded wall so no cost impact. To ensure there weren't any issues with him hitting electrical wire that I ran, I used the WIND LOCK 2-QC Hot Knife cutting a 1/2" channel all the way down to the poured concrete at a depth of 2.5" to set the wire runs. I backfilled the channels with Great Stuff- Cracks and Gaps which is yellow'ish so it was clearly visible. PRE-PLANNING: Only comment about electrical, plumbing and HVAC efforts, you really-really-really have to pre-plan each and every penetration and identify/install any sleeves you need in the ICF block before the concrete is poured. When I designed the house I used Chief Architect Lite Software. That package allowed me to easily identify where they needed to be placed and after we stacked the block with the bucking installed we used our WIND LOCK Hot Knife to add the sleeves + used the WIND LOCK Professional Foam Adhesive to bond them to the block. Think about it, every exterior light to be mounted on a wall, exhaust vent, dryer vent, all the Concentric Vents for the Direct Vent HVAC Equipment, HRV Fresh Air and Exhaust, exterior plugs, Water Frost Free Bibs, etc, etc, etc. My wife and I created a spread sheet to keep that list straight, and then add in the complication of navigating the open web floor trusses to bring the Concentric Vent thru and where the mechanical equipment must be installed to support that location, it was primal scream time at some points....... TECHNICAL TID-BITS As mentioned in a previous post, the most critical stage is setting the first 2 courses of block. If you don't have the footings level you'll start off thinking you know what you're doing (yea-right), skies blue and birds singing and all of a sudden you can't get the blocks to set side-by-side (gap getting greater as you go up in height) then you have to stop & unstack the wall, remove rebar and cut the block to re-establish the horizontal plane (been there done that). Besides the level issue you have to ensure the first two blocks will be anchored on the footings. To do that, Build Block strongly suggested that we cable tie the first two courses up-down & side-by-side. We found some heavy duty Boston Industrial 175 Tensile Strength 36 Inch Cable Ties on-line and went to work. The ties were placed on adjoining webs internal to the blocks and cinched tight. Also another very smart suggestion; add the same ties to all corner and adjoining blocks as you go up in height, side X side and Up/Down and lastly, do the top course just like the fist course. During the Contractor Certification Training by Build Block they emphasized; "Glue is a Friend" so I purchased several cases of WIND LOCK'S Professional Foam Adhesive. Wherever there was a slight gap in the adjoining blocks "GLUE", the first course to the concrete footing "GLUE", around all penetration sleeves "GLUE", around all bucking to adjoining blocks "GLUE", you get the drill. SOIL SURVEY: Be sure before you start down the path on one of these structures that you no-kidding understand the soil composition because we're talking an insane amount of weight. The more clay'ish the soil (in my case) the wider the footings + vertical and horizontal rebar considerations. You must understand your state's building codes, the International Building Code, International Residential Code and most important use of the ACI 318 or the PCA100 specs that give you a detailed road map in using concrete and its physical properties. To know if you're ready, you'll understand what "STIRRUPS" and "LENTILS" are and how they ensure all openings are properly supported. OVERALL FEEL OF THE HOUSE The house is ultra quiet, we are using Pella's Architectural Series windows and we can't hear a thing, open that window though and 200 feet away is a pond and those Spring Peeper Frogs are deafening, my wife and I just about have to dawn our ear plugs that I wear on the JD Tractor. It can be pouring out and wind blowing hard and you can hear a pin drop, no noise transfer thru the 13" depth walls. HVAC - When I spec'd out the HVAC system I paid a contractor to perform a "Manual J" and "Manual D" that identifies what we needed to heat/cool the rooms and the ducting sizing to get the air around. Since we installed PEX in basement slab + Slant-Fin Baseboard on the 1st floor the heat remains constant. Based on the Method D results, I stuffed typical 26 gauge ducting in the open web floor trusses to support the Forced air 95% efficient Furnace and matching A/C Coil and Condensing Unit. Nothing worse than building a home then finding out a back room doesn't get enough cooling in the heat of the summer. ENERGY WISE From Nov 1st thru Feb 22nd our total "propane" usage billing is $1,000, our total sq. ft. is 1,376 X 2. WOULD I DO IT AGAIN Right now where I'm sitting I'd say YES, however if I was in the middle of stacking the blocks and dealing with the rebar I'd say NO with a couple of explanatives thrown-in. Kind of like going to the dentist, right before you go I'd always like to opt out but after the fact I say it was well worth it. In summary unless you're a full time Builder involved in the day-to-day technical aspects of working with concrete, you'll have to dig in deep on the design details to the point you can converse with the subs, even talking on-site slump testing of the concrete.