Gary Fowler

Super Star Member

- Joined

- Jun 23, 2008

- Messages

- 11,917

- Location

- Bismarck Arkansas

- Tractor

- 2009 Kubota RTV 900, 2009 Kubota B26 TLB & 2010 model LS P7010

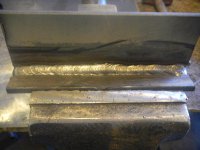

Everyone including myself put way more weld on than necessary. A 1/8" fillet all the way around on just the hook would hold much more force than any tractor could produce. The double plate is perhaps needed to spread the load and prevent tear out or bending of the FEL bucket (or maybe not) but we all like to be extra safe so when I put mine on my P 7010, I put on a 3/8" double that is 4" x 5" welded with a full 3/8" fillet all the way around plus it has a large plug weld in the center of the doubler (also not needed) and then the same 3/8 or larger weld on the hook. It looks better that way but no way is that much weld needed.

I don't get a lot of welding time in so when I get a chance to weld something, I go way overboard.

I don't get a lot of welding time in so when I get a chance to weld something, I go way overboard.