tshep

Gold Member

That create a picture?

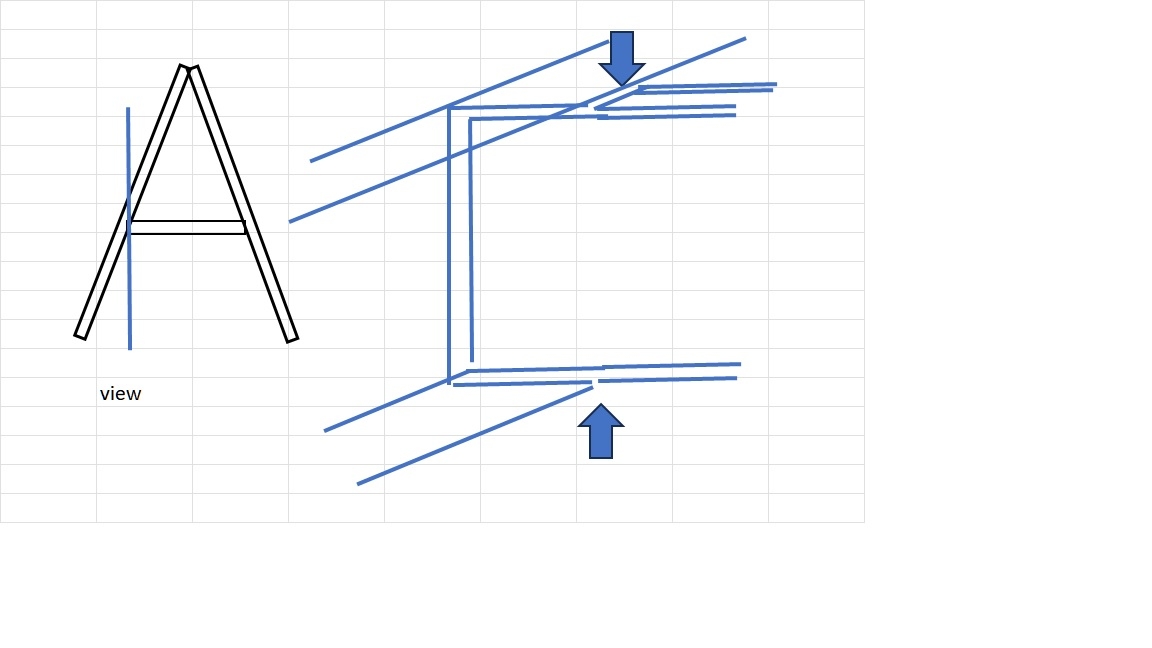

It is an aluminum trailer, 3500 lb range. The forward beams combine at an standard angle, with an angled hitch attached. There is a centered hole there that accepts a similar triangle flange with a lift poked through. It never raises enough to really get out of the way for curbs and such.

So I got a nice swivel lift that attaches to one of the beams.

Got it on (with my no-attachments) tractor on near the center of the beam, and the beam rotates enough to throw the lift angle way off.

I need to devise a tension member at the bottom of beam (to prevent rotation out), and a compression member at the top (to prevent rotation in).

Anything across the two will intersect them at an angle, and if not welded, will probably move forward over time.

I believe I need to buy say, 2 feet of similar beam, notch short flange so remaining wide flange fits into existing beams, and weld ONLY the inside edge short flange to other short flange where they meet (to protect the load bearing wide flange from holes or heat).

Better idea?

THX all.

It is an aluminum trailer, 3500 lb range. The forward beams combine at an standard angle, with an angled hitch attached. There is a centered hole there that accepts a similar triangle flange with a lift poked through. It never raises enough to really get out of the way for curbs and such.

So I got a nice swivel lift that attaches to one of the beams.

Got it on (with my no-attachments) tractor on near the center of the beam, and the beam rotates enough to throw the lift angle way off.

I need to devise a tension member at the bottom of beam (to prevent rotation out), and a compression member at the top (to prevent rotation in).

Anything across the two will intersect them at an angle, and if not welded, will probably move forward over time.

I believe I need to buy say, 2 feet of similar beam, notch short flange so remaining wide flange fits into existing beams, and weld ONLY the inside edge short flange to other short flange where they meet (to protect the load bearing wide flange from holes or heat).

Better idea?

THX all.

Last edited: