I have a good friend with the older model 47 snow blower attachment that runs on his 430 tractor. Unfortunately, the shaft that carries the impeller sheared off. And worse yet, JD only sells the entire gearbox for around $1400, not the individual components.

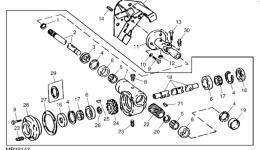

After disassembly, this appears to be a gear on a shaft that is a one-piece part. We were hopeful that the gear and bearing races were pressed onto the shaft with a key holding the gear in place. A machine shop took the part and put it on a 50 ton press and concluded that the shaft and gear are one piece when it didn't budge. I have attached a couple pics of the broken part.

So we're trying to think outside the box and exploring possibilities for repairing the gear/shaft part. The gear and shaft are both hardened.

So here's the question: Has anybody here had any success with repairing something like this? Any clever machinists out there?

After disassembly, this appears to be a gear on a shaft that is a one-piece part. We were hopeful that the gear and bearing races were pressed onto the shaft with a key holding the gear in place. A machine shop took the part and put it on a 50 ton press and concluded that the shaft and gear are one piece when it didn't budge. I have attached a couple pics of the broken part.

So we're trying to think outside the box and exploring possibilities for repairing the gear/shaft part. The gear and shaft are both hardened.

So here's the question: Has anybody here had any success with repairing something like this? Any clever machinists out there?

Last edited: