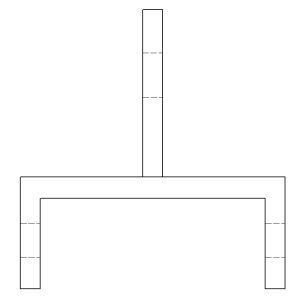

I'll try to spare you the complicated "verbal drawing" as much as possible. To modify my tiller to fit I-match I had a possible solution but wanted your thoughts on strength and choice of steel plate.

to make imatch fit:

I need to shorten the rise from lower pins to top pin, and I need to create a slightly wider attachment using standard male pins instead of the tillers current multiple specific "slots" with holes for cross pin.

So I thought if I bolt 1/4 inch (?) steel plate to one of the vertical slots using the existing pin hole, and then drill a hole in that plate 2.5 inches above that and insert new standard TSC lower male pins in that higher wider position . . .i'd be right on the dimensions. And i don't permanently mangle the tiller if I need to sell it.

Assuming that makes any sense, would a piece of steel plate say 5 inches high, 3 inches deep, with about 2.5 inches of that above current framing with a male pin be sufficient to hold each side of the 500lb 60" tiller? Or would the weight on each pin bend the plate inward and up?

What would you suggest for thickness and would a hacksaw and drill do the job on that type of steel? Not that I know where to buy plate steel . . but maybe I can salvage from something.

Thanks for any thoughts you have!

to make imatch fit:

I need to shorten the rise from lower pins to top pin, and I need to create a slightly wider attachment using standard male pins instead of the tillers current multiple specific "slots" with holes for cross pin.

So I thought if I bolt 1/4 inch (?) steel plate to one of the vertical slots using the existing pin hole, and then drill a hole in that plate 2.5 inches above that and insert new standard TSC lower male pins in that higher wider position . . .i'd be right on the dimensions. And i don't permanently mangle the tiller if I need to sell it.

Assuming that makes any sense, would a piece of steel plate say 5 inches high, 3 inches deep, with about 2.5 inches of that above current framing with a male pin be sufficient to hold each side of the 500lb 60" tiller? Or would the weight on each pin bend the plate inward and up?

What would you suggest for thickness and would a hacksaw and drill do the job on that type of steel? Not that I know where to buy plate steel . . but maybe I can salvage from something.

Thanks for any thoughts you have!