OP

dickfoster

Elite Member

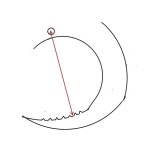

Go to Michigan Iron and Equipment's website I "think" they custom make the rippers to any backhoe. They actually have a pretty ingenious way of doing it, they have a PDF form with a diagram that tells you the exact points that they need measurements from to build your particular attachment. They are a Kioti seller and I have purchased a few things from them always ship fast and prices are reasonable.

That is pretty much the same thing Bro Tek does. They have you measure your bucket actually then design and make the tooth to fit your hoe from those numbers.