Hello all, new tractor owner - just got a NH TC24DA last month (came w/FEL and 60in box blade). Found a king kutter 48in XB tiller for a great price and grabbed it. Attached it to the 3pt tonight and started to measure the shaft wanting to size / cut it and try out the tiller. Question is on the cutting. I have viewed some on-line videos about cutting and it look pretty straight forward. When I started to measure my set up it looked like the length between my PTO and the slip clutch was borderline. The KK manual states that if the overlap has less than 6 inches DO NOT USE. Mine is close and I think I am just not wanting not to make a newbie mistake before cutting. From the attached pics should I be worried or just make the cut and if I have a little less than 6 in I should still be ok? Also, most on-line directions say to not engage the spline on the output PTO shaft (just put it to the end) when measuring for the cut. The kk manual says to fully engage the shaft before cutting. To me this seems wrong, I will then not be able to disconnect the shaft with the 3pt attached? Any help is great. Thanks! By the way this is the best purchase I have ever made! Having a great time learning from the forums and operating the tractor on my land.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tiller PTO shaft cutting

- Thread starter tedf

- Start date

- Views: 14365

/ PTO shaft cutting

#1

joecdeere

Veteran Member

- Joined

- Apr 13, 2002

- Messages

- 1,709

- Location

- Cumming,Georgia

- Tractor

- 1948 Allis UC Hi-Crop Cane 1941 Allis WC 1948 Allis G with loader, 1948 Allis G with dual disc 1948 Allis G 1948 Allis G 1949 Allis G 1954 Allis G 1959 Ferguson TO-35 1972 MF 135 1979 Power King 2418 1989 Ford 345C TLB

Smallplot

Gold Member

- Joined

- Sep 9, 2011

- Messages

- 295

- Location

- Pike County Illinois

- Tractor

- 1974 IH 1066, 1969 IH 756/FEL, and 2011 TYM T603 Cab/FEL

Everythingattachments.com has a good video on this subject. Have you checked it out. Video is available on youtube.

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 23,144

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

Try this:

How to Measure and Cut a Tractor PTO Shaft - YouTube

BTW, you do measure from the end of the PTO stub shaft....the video explains it.

Also, I've always read 4" of overlap...and the instructions joecdeere posted contradicts the Everything Attachments video as far as cutting the shaft and shield the same length as well as connecting both the implement and tractor ends.

How to Measure and Cut a Tractor PTO Shaft - YouTube

BTW, you do measure from the end of the PTO stub shaft....the video explains it.

Also, I've always read 4" of overlap...and the instructions joecdeere posted contradicts the Everything Attachments video as far as cutting the shaft and shield the same length as well as connecting both the implement and tractor ends.

SSdoxie

Elite Member

If it were mine I would first measure and cut with shaft locked on the PTO. If it is too long to hookup the PTO after the first cut you can always cut end each end a little more. Lot easier to cut it twice than add material back on.

Chilly807

Elite Member

Your best bet is to follow the instructions that came with the shaft and tiller. I just went through this with a log winch, the directions were different from each manufacturer.

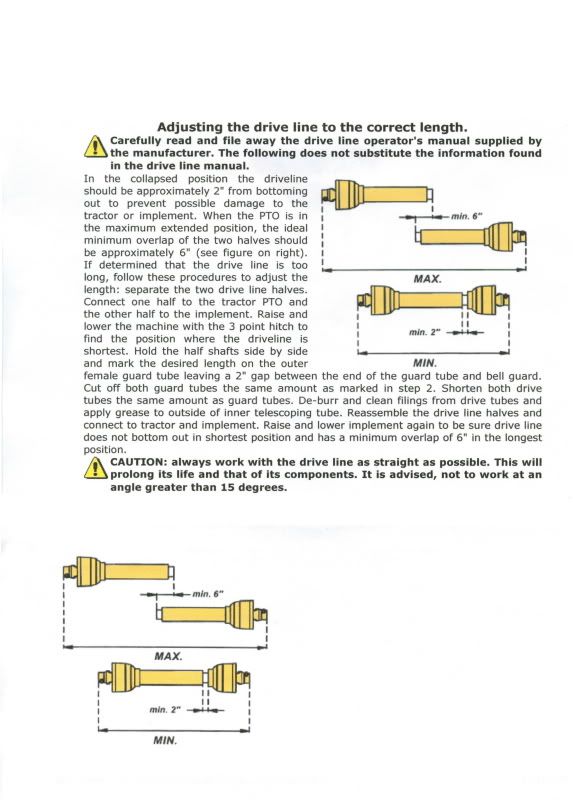

The end result you're looking for is that the shafts do not bottom out and bind when the implement is at the closest point to the tractor, and also has at least 6 inches of overlap at the longest point from the tractor. The distances will change as you raise or lower the tiller, so spend some time with both ends of the shaft removed and take some careful measurements.

I measured the total collapsed length of the shaft (in my case I measured from the center of the locking grooves on the PTO output and input shafts) as I received it, then compared that to the minimum distance between the tractor and mounted winch at the same location on the splines.

In my case, the collapsed shaft was 28 inches long at the two points I measured, and the closest distance between tractor and winch at the same two points was just under 23 inches. To be safe, I cut off 6 inches from each end, which gives me almost an inch of free play before anything binds. According to the shaft manufacturer, they want to see 50% engagement of each end of the shaft at full operating extension.

So, I needed at least 7 inches of engagement if each end of the shaft was 14 inches long... I have that and more, and still have clearance at the closest point.

It's hard to get your head around this, I measured more than once before cutting the shafts. I had hoped they would be "just right" as they came, but it wasn't going to be that easy.

The tricky part is being sure you're measuring to the same point on both the driveshafts and the PTO stub and input shafts, and also allowing for the bend in the driveline caused by the flexing universal joints.

Be careful... a driveline coming apart isn't good, but neither is breaking the PTO because it didn't have enough room with the tiller fully raised or lowered. Usually the closest point is with the PTO and tiller input shafts both level, normally this is with the tiller about halfway up, but each situation can be different.

Sean

The end result you're looking for is that the shafts do not bottom out and bind when the implement is at the closest point to the tractor, and also has at least 6 inches of overlap at the longest point from the tractor. The distances will change as you raise or lower the tiller, so spend some time with both ends of the shaft removed and take some careful measurements.

I measured the total collapsed length of the shaft (in my case I measured from the center of the locking grooves on the PTO output and input shafts) as I received it, then compared that to the minimum distance between the tractor and mounted winch at the same location on the splines.

In my case, the collapsed shaft was 28 inches long at the two points I measured, and the closest distance between tractor and winch at the same two points was just under 23 inches. To be safe, I cut off 6 inches from each end, which gives me almost an inch of free play before anything binds. According to the shaft manufacturer, they want to see 50% engagement of each end of the shaft at full operating extension.

So, I needed at least 7 inches of engagement if each end of the shaft was 14 inches long... I have that and more, and still have clearance at the closest point.

It's hard to get your head around this, I measured more than once before cutting the shafts. I had hoped they would be "just right" as they came, but it wasn't going to be that easy.

The tricky part is being sure you're measuring to the same point on both the driveshafts and the PTO stub and input shafts, and also allowing for the bend in the driveline caused by the flexing universal joints.

Be careful... a driveline coming apart isn't good, but neither is breaking the PTO because it didn't have enough room with the tiller fully raised or lowered. Usually the closest point is with the PTO and tiller input shafts both level, normally this is with the tiller about halfway up, but each situation can be different.

Sean