Shield Arc

Super Member

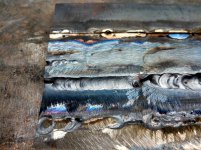

I have been half tempted to hold two rods together and feed them at the same time, essentially making a 1/8" filler, but I just try stabbing the 1/16" in faster instead.

Joshua the best Tig weldor I was ever around, I think he could Tig weld faster than I could stick weld! I seen him take two filler rods, place the ends in a vice, chuck the other ends in a drill motor, and spin the rods over each other to make one rod. Worked great for him!