Shield Arc

Super Member

This subject was brought up in another thread. Not wanting to high jack SSdoxie's thread, I started another one.

I mentioned in the other thread a lot of people run 6013 on DCEN, or straight polarity when welding sheet metal for less penetration. I also mentioned that when I do open root with 7018 I use DCEN. Mark @ Everlast and Arc weld two extremely knowledgeable weldors suggested I try open root with 6010 on DCEN. Don't know why I never thought of doing that! But I've never been good at thinking out of the box, I generally only do as I was taught, or learned myself is the best way to do things.

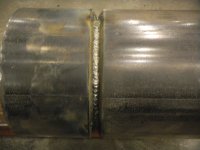

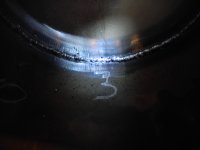

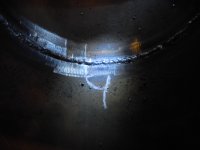

All I can say is WOW! I was really impressed with how this ran! I thought it was strange with the same joint prep I had to run 5 to 10-amps less than I normally do on DCEP. This is 6-inch sch 80 pipe 5-G, with 1/8-inch Lincoln 5P+ 6010.

I don't know why, but I thought I'd do a little side by side comparison with my Everlast PowerArc 200, and my Lincoln V350-Pro. Strange how a $300.00 import welder welds every bit as nice as a $5,000.00 welder made in Cleveland! Don't get me wrong the V350-Pro can do so much more than the PA-200, but when it comes to stick welding I can't tell any difference at all in the machines.

Here are the pictures, I just noticed the flash didn't work on some of the pictures of the welds the V350-Pro did. I need to get someone to teach me how to take pictures!

I mentioned in the other thread a lot of people run 6013 on DCEN, or straight polarity when welding sheet metal for less penetration. I also mentioned that when I do open root with 7018 I use DCEN. Mark @ Everlast and Arc weld two extremely knowledgeable weldors suggested I try open root with 6010 on DCEN. Don't know why I never thought of doing that! But I've never been good at thinking out of the box, I generally only do as I was taught, or learned myself is the best way to do things.

All I can say is WOW! I was really impressed with how this ran! I thought it was strange with the same joint prep I had to run 5 to 10-amps less than I normally do on DCEP. This is 6-inch sch 80 pipe 5-G, with 1/8-inch Lincoln 5P+ 6010.

I don't know why, but I thought I'd do a little side by side comparison with my Everlast PowerArc 200, and my Lincoln V350-Pro. Strange how a $300.00 import welder welds every bit as nice as a $5,000.00 welder made in Cleveland! Don't get me wrong the V350-Pro can do so much more than the PA-200, but when it comes to stick welding I can't tell any difference at all in the machines.

Here are the pictures, I just noticed the flash didn't work on some of the pictures of the welds the V350-Pro did. I need to get someone to teach me how to take pictures!

Attachments

-

200 tack.JPG235.9 KB · Views: 331

200 tack.JPG235.9 KB · Views: 331 -

2006.JPG239.4 KB · Views: 440

2006.JPG239.4 KB · Views: 440 -

2003.JPG237.2 KB · Views: 306

2003.JPG237.2 KB · Views: 306 -

2009.JPG236.7 KB · Views: 1,816

2009.JPG236.7 KB · Views: 1,816 -

20012.JPG234.8 KB · Views: 421

20012.JPG234.8 KB · Views: 421 -

200 outside.JPG234.7 KB · Views: 355

200 outside.JPG234.7 KB · Views: 355 -

3506.JPG239.2 KB · Views: 437

3506.JPG239.2 KB · Views: 437 -

3503.JPG222.7 KB · Views: 271

3503.JPG222.7 KB · Views: 271 -

3509.JPG231.3 KB · Views: 246

3509.JPG231.3 KB · Views: 246 -

35012.JPG229.7 KB · Views: 270

35012.JPG229.7 KB · Views: 270