sounds like it needs this....(from the on-line owners manual)

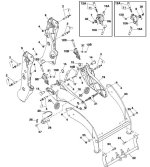

Checking Parking Latch Cap Screw Adjustment

W20247-UN-08JAN09

W20270-UN-12JAN09

Left-Hand Side Shown

A - Cap Screw

B - Latch

C - Locking Screw

D - Latch Pin

E - Leaf Spring

F - Brace Pad

G - Mast Pad

Be sure loader is equipped with materials bucket, 4-in-1 bucket or grapple bucket.

Attach loader to tractor (See Attach Loader section.)

Start tractor engine and lower ballast box or rear implement to the ground.

Dump bucket 10ï½°?0ï½° and lower to ground.

Retract lift cylinders, raising front wheels 25?0 mm (1? in.) off ground. (Do not retract lift cylinders completely.)

On both sides, make sure latch (B) is fully seated against brace pad (F) and latch pin (D) is engaged with leaf spring (E). Cap screw (A) should contact mast pad (G). If not, adjust each cap screw as follows:

Loosen locking screw (C).

Turn cap screw (A) until it makes contact with mast pad but latch is still free to rotate.

Tighten locking screw to specification.

Item Measurement Specification

Locking Screw Torque 25 N瀕 (221 lb-in.)

NOTE: To disable the quick park feature, loosen locking screw (B), turn cap screw (A) until it is tight against mast pad (G) so latch (C) cannot rotate freely. Tighten locking screw to specification.

Extend lift cylinders to lower tractor to ground.

Shut off tractor engine and remove key.