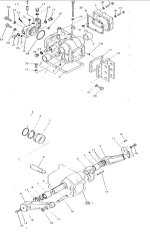

Ok, so here is part of the disassembly. I already had one fender off of the tractor in the process of working on the brakes, so that was a fortunate coincidence. I put a bunch of alignment marks on my lift arms and housing to help with re-assembly, but then noticed there are already some case markings and stuff to help with that...no harm in more. I disconnected the lift lever link on the right side. I removed the left lift arm with no problem...just take off the bolt and washer and tap it off the splines. I then removed the right bolt and washer. There is an alignment pin that you will have to contend with...mine was a little rusty and I had to work it around a bit to remove the washer. I removed the back toplink cover to expose the rock shaft, arm, and piston rod. The cover has two alignment pins that are really tight. It took a lot of smacks with a dead-blow hammer to loosen it. Once all that was off, I pulled the rock shaft out (I think that's the term for the spline shaft that is doing the lifting). Make sure to catch the multiple o-rings that are there along with the two splined sleeves. I had to push the rock shaft to the left, then to the right to remove all 4 o-rings and 2 sleeves. I found a pasty splined residue where I think my rock-shaft seals used to be a solid...So, I guess I need to get a couple of those. I thought this was old grease or maybe some dirt that had gotten caked into the splines of the shaft, but when looking at he parts diagram above, I realized THOSE USED TO BE PARTS! Now they are moist paste. Something very important to note...Because my piston is all the way to the back of the cylinder, I wasn't able to remove the piston rod #4 and arm #5 together. I used a piece of wire and a block of wood to hold still (for lack of a better word) the "elbow" of the two out of the back opening. Then I used a hammer and properly sized metal drift to knock the pin inward on one side. I am right-handed, so I knocked in the right side of the pin until it stuck further out on the left of the piston rod #4. I didn't have to remove the pin to disconnect the rod from the arm. Once it was about a quarter of an inch further left, the two slipped apart, and I could remove the two individually. Here are some pictures.

My lift arms removed...forced perspective makes one look bigger than the other, but that's just an optical illusion. They are the same size. In fact, they are identical and can be interchanged, I think.

(Above) the piston rod #4 and arm #5 together again after removal. (Below) the rock shaft #6, splined sleeves #7 and end bolt and washers. O-rings are not pictured. I left them around the gear shift lever on the tractor. Also note, no seals #8 as mine were powdered!

Here is the elbow I talk about above...I think there is supposed to be some play in this, but it does seem a bit excessive. Seems like a bushing or something should be filling some of this gap between the pin and the arm #4.

Here is the housing with stuff removed.

Here is a picture of the rear of the piston with everything above removed. I'll remove the 3-point cylinder head from the front of the assembly when I get a chance and attempt to remove the piston from the rear and evaluate the condition of the cylinder walls, o-ring and piston.