Kyle_in_Tex

Super Star Member

My 4310 uses cruise along with the system that keeps it from bogging the engine to relegate the speed. But instead of adding more power, it just reduces speed to allow the engine to catch up (unless you have it at full power already). I rarely use this feature combination.

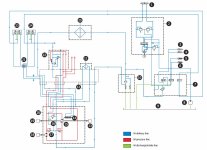

Your system looks complicated, at least until you figure out mentally what it is supposed to do.

Your system looks complicated, at least until you figure out mentally what it is supposed to do.