ArlyA

Super Star Member

- Joined

- Mar 18, 2016

- Messages

- 13,933

- Tractor

- Outlander1000 6x6, Ego lawn mower and shopping for tractor

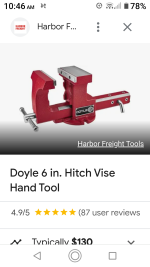

I have nearly no work space, so for a small welding table, was dreaming of building a small one, with the top 20" x 20 x 5/8 plate and mount in on a spit truck rim as its base. Kinda like this photo.