I use 3/8" AR400 plate. We've hit it with 44, .308 and plenty of .223. A few M1 Garands had fun with, too.

Steel core (M855 "green tip") will put pock marks in it, and the edges are always going to get a little dinged up. Mine have lasted five or so years and seen many thousands of hits (and quite a few misses - I teach newbies).

If you are looking to put these together yourself, my suggestion is to look at the exact brand of steel. AR is not "armor plate" like a lot of people think, it stands for "Abrasion Resistant". That means there are different steels that are designed for different segments of the abrasion market. You are correct, most AR steels are made for construction equipment.

The big issue welding them is the narrow range some have: you need to preheat between 350 and 380 F for some, and then weld. If you go too high, you blow the tensile strength. Too low and you'll get cracks. Check the manufacturer data sheet, buy a crayon and get it right. I have stick and flux-core MIG'd mild steel brackets to the back. Ours stay out all year, 24/7 hot and cold and in the rain, snow and ice. We shoot them year round. Keep some Krylon on them and they do fine for 3-5 years before a repair.

ThomasH is right: they are consumables. That said, they will last a long time. You don't need to baby them, just fix the eventual weld cracks and carry on. One of the things my guests like to do is check the back of the older steels and see who is developing cracks. There is a contest to see who can make it come apart. Each steel last years on the weld, and I think I've tagged them all this last year. So no more contest winners for a few more years. I am at the point of replacing a few that are chewed up pretty good, though.

I suggest cutting with a plasma torch because it leaves a nicer edge. Grinding abrasion resistant steel is no fun, at all. Get it clean the first time and save the hassle.

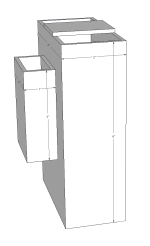

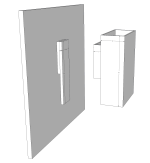

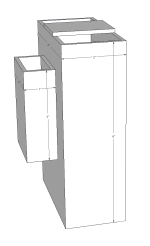

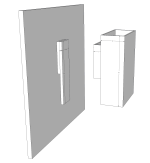

As for brackets, I use 1/8" rectangular tubes that fit over a wooden 2x4. To that I attach a 2x1 tube, then just hang them over the wood. No bends and it just uses basic bar and tube stock. It's a great basic welding project. The back of the steel has a little hanger. Easy, peezy, lemon squeezy, as my daughter likes to say. Check the attached drawing I made up. Click them - they should expand.

Another note, plan on the hanger causing the steel to angle down a bit to help deflect rounds to the ground. You do not want to shoot into a parallel plane.

Caveat: this is the internet and I am nobody so everything I say above is so wrong that if you follow it and get hurt, you are a dummy for trusting what I say. Don't come back on me. Guns are icky suck and people who shoot them are just asking to lose an eye, or worse!