I am starting my remotes project and sure would appreciate help

I am diving into this project now that I saved enough to get the first phase completed. If you all could help me through this I sure would appreciate it. I haven't ever worked with hydraulics!

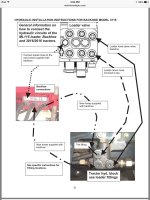

I purchased the valves and am laying them out. Here is my plan so far. I don't have much room so I am using two, two spool valves and I am placing one on each side of my seat. They are both 8gpm Prince Wolverine valves. For the t and t I am going to have the side link with float. The other three are standard spring to center valves.

The cardboard is a template for a mounting plate that I am planning on making out of 1/4" steel.

I am detaching the PB and return port from the loader valve and routing those lines towards the new remotes. I plan to plumb my pressure in on the first new valve from the PB port on the loader valve then from the PB from valve one to the pressure in on valve two. Then I will come from PB out from valve two and I am going to join up with the detached line that was originally from the PB out on the Loader valve so it feeds my hydraulic block and goes to the three point. Does this sound right?

For the return to tank lines I am joining them from both valves together and running the lines toward the disconnected line from the loader valve return. I will add a new line from the loader valve return and I will t them all together to get the fluid back to the hydraulic block. Is this ok too?

Are there any heat concerns from sending the fluid through three valves? My pump is rated at 7.8 gpm.

Now I need to think about the load check comments from JJ. I am going to look for those settings in my loader manual.

.