What I need is someone here to help me with the correct way to set gear backlash in the front axel case. I found a very worn lower bevel gear in the bottom of the gearcase on the rt. side while I was replacing the seal. I ended up taking the whole case completely apart for cleaning and to check all of the bearings after seeing all the metal missing from that gear. The bearing on that gear was bad also but all the others were OK. The pics of the gear look to me like either a bad heat treatment of that gear or an incorrect setup of the lash originally. Notice that there is almost equal damage to each tooth and it is also in the same area of each tooth. I would not expect that kind of damage if a piece of something was rattling around in there (?).

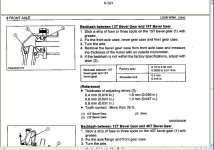

When I reassembled things, the gearcase was WAAAY too tight when I tried to turn the hub. Since I reused the original shim, I am guessing that either the gearcase was improperly shimmed originally or ?? If I remove the shim (it is a 2.0mm;the parts book shows 7 thicknesses from 0.8mm - 2.6mm) there is a bit more lash than I would consider ideal.

The odd thing to me is that the gear can be driven upward until it hits the casting but this places it more deeply into the ring gear for the hub further decreasing lash + increasing binding. Does this gear and bearing assy just "sit" (via gravity) down against the shim(s) and snap ring in the bottom of the gearcase since there is nothing that shows any shims between the gear and the bearing?? I guess ther isn't anything that would make the gear and bearing want to move upward under operating conditions but it seems a bit of an odd design to anyone used to automotive and marine gearboxes.

When I reassembled things, the gearcase was WAAAY too tight when I tried to turn the hub. Since I reused the original shim, I am guessing that either the gearcase was improperly shimmed originally or ?? If I remove the shim (it is a 2.0mm;the parts book shows 7 thicknesses from 0.8mm - 2.6mm) there is a bit more lash than I would consider ideal.

The odd thing to me is that the gear can be driven upward until it hits the casting but this places it more deeply into the ring gear for the hub further decreasing lash + increasing binding. Does this gear and bearing assy just "sit" (via gravity) down against the shim(s) and snap ring in the bottom of the gearcase since there is nothing that shows any shims between the gear and the bearing?? I guess ther isn't anything that would make the gear and bearing want to move upward under operating conditions but it seems a bit of an odd design to anyone used to automotive and marine gearboxes.